Meta-aramid (aramid 1313), chemically known as poly(m-phenylene isophthalamide) (PMIA), is a soft, white, fine, fluffy and shiny fiber. PMIA is a regularly arranged zigzag macromolecule.

PMIA fiber is synthesized by low-temperature polycondensation of isophthaloyl chloride (ICI) and metaphenylenediamine (MPD). The polymerization reaction formula is as follows:

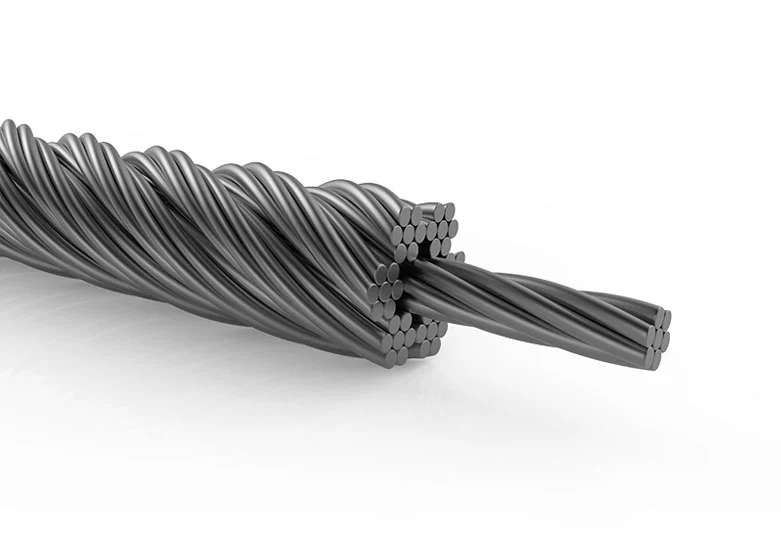

PMIA fiber is polymerized primarily through low-temperature polymerization, interfacial polymerization, vapor-phase polymerization, and emulsion polymerization, with low-temperature polycondensation being the most widely used. Currently, three main production processes for PMIA fiber are employed: low-temperature solution polycondensation followed by wet spinning; low-temperature continuous polymerization followed by dry-wet spinning; and interfacial polycondensation followed by wet spinning. Aramid yarn is revolutionizing industries with its exceptional strength-to-weight ratio and unparalleled resistance to heat, chemicals, and abrasion.

Results and Characteristics:

The amide groups in PMIA fiber macromolecules are interconnected through meta-phenyl groups. These covalent bonds lack conjugation, resulting in lower internal rotational potential energy than PPTA (para-aramid) fibers, and the macromolecular chain exhibits a flexible structure. PMIA fiber exhibits a triclinic crystal structure, with hydrogen bonds occurring on two crystal planes and arranged in a lattice pattern. The strong interaction of these hydrogen bonds makes PMIA fiber chemically very stable, while also exhibiting excellent heat and chemical resistance and flame retardancy. The microstructure of PMIA fiber exhibits a distinct fibril structure. High energy barriers for rotation between the phenylene groups and the amide groups, as well as between the C-N bonds, prevent the molecular chains from forming a fully straight chain conformation.

Performance characteristics From a structural point of view, the meta-aramid molecule is a linear macromolecule composed of meta-phenyl groups connected by amide groups. In its crystal, hydrogen bonds exist on two planes, such as a lattice arrangement, thus forming a three-dimensional structure of hydrogen bridges. Due to the strong effect of hydrogen bonds, the chemical structure of meta-aramid is stable. (1) Excellent heat resistance. It can be used for a long time at 200°C and has good dimensional stability. (2) Super strong flame retardancy. It is an inherently flame retardant fiber with a limiting oxygen index (LOI) value of ≥28%. It will not spontaneously combust, melt or produce melting in the air; when encountering extremely high temperatures, the fiber will rapidly expand and carbonize to form a unique insulation screen. (3) Outstanding electrical insulation. Aramid paper made of aramid can make the temperature resistance and insulation performance of electromechanical products reach H level (180°C). (4) Excellent chemical stability. It is resistant to corrosion by most chemical substances, can withstand high concentrations of inorganic acids, and has good alkali resistance at room temperature. (5) It is not easy to dye, difficult to melt spinning, and has poor stability to sunlight.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt