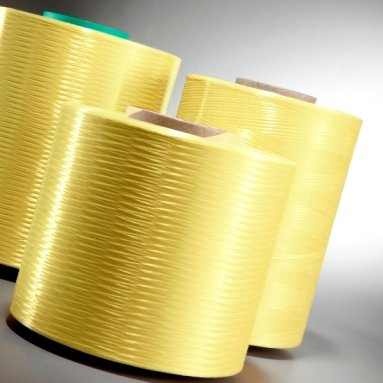

The development of new energy vehicles has brought tremendous opportunities for the application of aramid fibers and aramid/polyester composite cords. Especially since the beginning of the 21st century, due to environmental protection requirements, European countries have taken the lead in implementing labeling laws in the tire industry, setting standards for tire noise, rolling resistance, and grip on wet surfaces. To meet these technical indicators, global tire design engineers have optimized tire structure, tread pattern, and compound design, while also selecting the best materials for the tire's skeleton. In high-performance passenger car radial tires and new energy vehicle tires, aramid or aramid/polyester composite cords have replaced nylon 66 as the crown layer, thus ensuring compliance with labeling laws and the performance requirements of new energy vehicles. Due to tire manufacturing costs, aramid and its composite cords are currently mainly used in high-performance passenger car tires and some electric vehicle tires. Statistics show that high-performance tires account for more than 60% of the global market, and all original equipment tires from European and American automakers are high-performance tires. In 2023, at least 150 million tires used aramid/polyester composite cord crown layers; more than 60% of original equipment tires for new energy vehicles use composite cords in their crown layer. Statistics show that global production of new energy vehicles exceeded 15 million units in 2023, requiring 60 million tires. Assuming an average usage of 0.10 kg per tire, the consumption of aramid and its composite cords in passenger car tires alone reached over 20,000 tons in 2023. All-steel radial truck and bus tires, engineering tires, and agricultural radial tires all utilize aramid or its composite cords in their design and construction, primarily to enhance tire load-bearing capacity and improve product quality. However, due to the involvement of tire companies' key technologies and core competitiveness, accurate data on the specifications, types, and quantities of cords used is unavailable. With the implementation of the third phase of the European tire labeling regulations, tire performance requirements are becoming more stringent, demanding ultra-low rolling resistance, longer service life, and more reliable safety performance, especially for electric vehicles requiring increasingly longer range on a single charge. According to EU regulations, the sale of gasoline-powered vehicles will cease within the EU by 2035. Based on current trends in new energy vehicle development, global sales of new energy vehicles are projected to exceed 50 million units by 2030, requiring 200 million original equipment tires. The social ownership of high-end sedans and electric vehicles will require approximately 600 million tires. Improved tire performance inevitably relies on new skeleton materials. According to previous research on the application of aramid and its composite cords in tires, to ensure compliance with automotive performance requirements, tire manufacturers will extensively use aramid and its composite cords in the tire carcass and crown layer. Under favorable operating conditions, all-fiber radial tires can replace semi-steel radial tires. After decades of research and development, aramid synthesis and spinning technologies in China are now highly mature. During the 14th Five-Year Plan period, several companies have commenced production, achieving an annual aramid cord production capacity of over 30,000 tons. Their product quality has approached or reached the level of similar foreign products. Domestic tire companies have mastered the application technology of aramid in tires, and aramid tires and other products will undoubtedly bring significant economic benefits to users and society. In summary, aramid tires offer advantages such as low weight, low rolling resistance, good puncture and wear resistance, and good vehicle handling stability. Due to their high cost-effectiveness, they are expected to be highly profitable for high-performance tires and new energy vehicle tires. As domestic aramid production capacity increases, prices will continue to decrease, and the application of aramid and its composite cords in tires will become increasingly widespread.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt