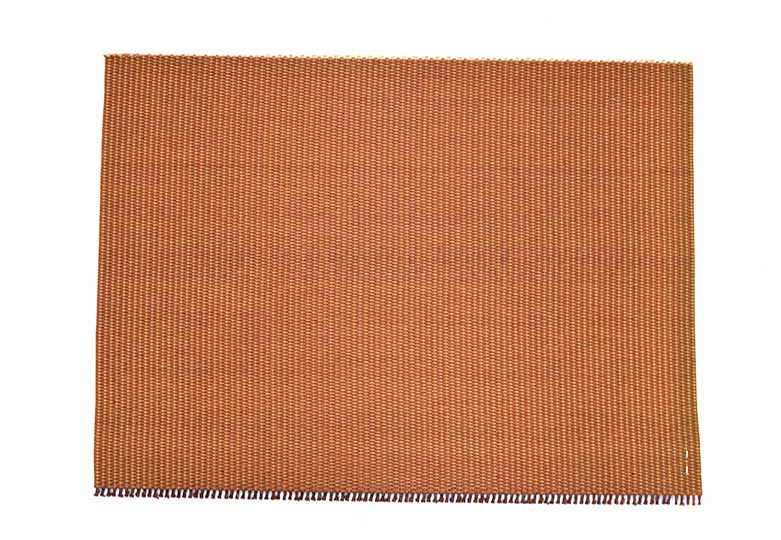

For several geotextile applications, longevity and durability are important factors in order to fulfill their function in soil reinforcement and protection. However, geotextiles with a much shorter life-span, which are designed to degrade after a certain time period, are in demand.

Biodegradable geotextiles are perfect for applications where once they have completed their task they biodegrade and disappear from view without the generation of persistent microplastics. These materials are used for preventing soil erosion until the seeded vegetation can take over this function or the floor is sufficiently consolidated. Thus, the geotextile should degrade after a couple of months or years into environmentally compatible components, which obviates the need of material re-collection and recovery. It also overcomes the emerging environmental issues with polypropylene (PP) and polyethylene terephthalate (PET) geotextiles concerning soil pollution and accumulation of microplastics.

The field of biodegradable geotextiles is rapidly gaining attention due to its potential environmental benefits and solution to the formation of microplastics from PP and PET geotextiles. A relative newcomer to this space is PBS which can solve the above problems. PBS is attracting increased attention for geotextiles due to the potential for bio-based production, as well as its balanced properties, enhanced processability, and excellent biodegradability.

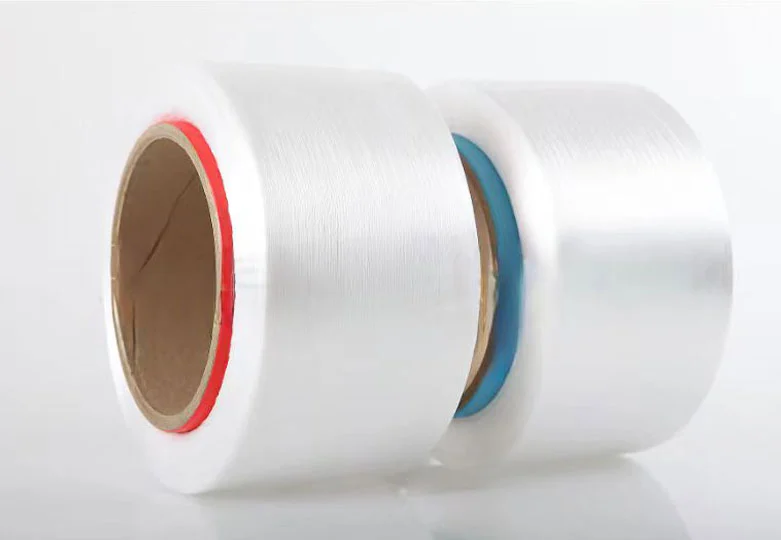

PBS is a biodegradable aliphatic polyester with excellent biodegradability, as well as thermal/UV and mechanical properties, which makes it suitable for the textile industry usage as a filament and a split yarn. The monomers can either be derived from petrochemical or bio-based chemicals (bacterial fermentation) and the latter is called bio-based poly (butylene succinate) or Bio-PBS.

PBS is a white crystalline thermoplastic polymer with a density of 1.25 g/cm3, a melting point (Tm) in the range of 90–120 °C, and a low glass transition temperature (Tg) of about −45 to −10 °C.

PBS has properties that are comparable to PP and PET thus making it ideal for geotextiles. PBS can be used to make 100% biodegradable, mechanically bonded nonwoven geotextiles. Due to its certified biodegradability, residues of the product do not harm the environment. Also, PBS can be made UV-resistant and therefore be used in uncovered applications. PBS geotextiles’ excellent mechanical properties allow them to resist mechanical stresses during installation and construction.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt