Behind every high-performance tire, hose, or seal lies the unsung hero — raw material for rubber products. At YUSHENG, we supply industry-leading raw materials for rubber products. Each raw material for rubber products in our inventory undergoes rigorous quality control.

Our raw materials for rubber products deliver exceptional flexibility, changeability, strength, and tear strength. Additionally, these raw materials for rubber products demonstrate good impermeability, are resistant to acids and alkalis, and provide effective insulation. These properties are crucial for ensuring durability and performance.

1、Natural rubber (NR)

The raw material of natural rubber comes from the rubber plant tree. Its advantages are: good elasticity, high strength, good insulation, small deformation, easy processing. Its disadvantages are: it is not oil resistant, poor temperature resistance, easy to age, and is generally used in combination. It is generally used to produce automobile tyres and some shock-absorbing and wear-resistant rubber parts.

2、Synthetic rubber

Synthetic rubber products have: SBR, NBR, BR, EPDM, IIR, CR, ACM, HNBR, CSM, FKM, MVQ, etc.

(1) Ethylene propylene rubber (EPDM)

Advantages: excellent ageing resistance, weather resistance, good electrical insulation, good impact elasticity, oil resistance.

Disadvantages: slow vulcanisation speed, self-adhesive properties, poor hot tear performance, poor processing performance.

Uses: Manufacture of heat-resistant transport belts, steam hoses, chemical-resistant seals, shock-absorbing pads and waterproof materials and automotive leather bowls and rings.

(2) Nitrile rubber (NBR)

Advantages: excellent oil resistance, but also has good heat resistance, ageing resistance, wear resistance, corrosion resistance and other properties.

Disadvantages: cold resistance, acid resistance, electrical insulation and other properties are poor, and resistance to tear strength is poor.

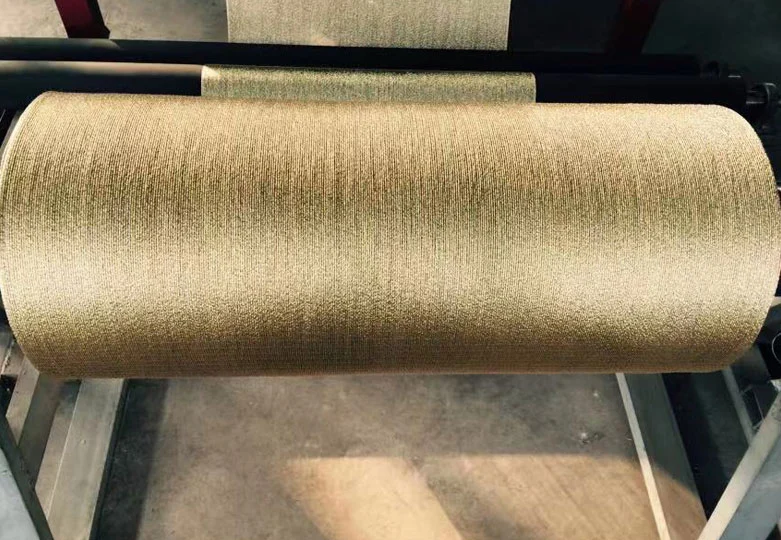

Uses: Mainly used in the manufacture of oil seals, shaft seals and gaskets (O-rings) and other products, but also used in the manufacture of oil-resistant hoses, transport belts, rubber rollers, vacuum hoses, shock-absorbing products and textile accessories.

(3) Styrene butadiene rubber (SBR)

Advantages: heat resistance, ageing resistance and wear resistance are good.

Disadvantages: cold resistance, elasticity, flexural disturbance, cracking, tear resistance and other performance is poor, and processing performance is poor plasticity change is small, calendering press out deformation, poor self-adhesion.

Uses: SBR rubber products are mainly used for pneumatic tyres, followed by rubber shoes, hoses, tapes, rubber rollers, rubber cloth and model products, hoover seals, such as suction mouth seals, etc.

(4) Neoprene (CR)

Advantages: flexural disturbance resistance, heat resistance, ageing resistance, acid and alkali resistance, and good elasticity, good airtightness. Has cold resistance and water resistance.

Disadvantages: poor storage stability, easy to crystallise, poor electrical insulation.

Uses: Mainly used for the production of rubber parts in home appliances and air conditioners.

(5) Butadiene rubber or polybutadiene rubber (BR)

Advantages: elasticity, low temperature resistance, wear resistance is good.

Disadvantages: low tensile strength, tear strength, poor resistance to wet slippage, poor adhesion.

Uses: mainly used in the manufacture of tyres, rubber materials can also be used to manufacture wear-resistant products (such as rubber shoes, rubber rollers), cold-resistant products and anti-vibration products.

(6) Butyl rubber (IIR)

Advantages: the most important feature is good airtightness, weather aging, light aging, chemical resistance are excellent, and high temperature, cold resistance is better, long-term working temperature can be below 130 ℃; absorb shock or vibration absorption effect is better, electrical insulation is better.

Disadvantages: less elastic than natural rubber, slower curing speed, processing performance, poor adhesion.

Uses: Butyl rubber products are most suitable for inflatable inner tubes, followed by underground cables, high-voltage cables, radiation-proof gloves, chemical equipment lining and shock-proof rubber raw material products, etc.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt

.jpg)