In addition to rubber, fillers such as silica are essential to tire assembly. Silica, for example, helps to optimize characteristics such as grip, rolling resistance and tire life. In the future, rice husks will be used as the source material for sustainably produced silica. Rice husks are a waste product of rice production and cannot be used as food or animal feed. Silica derived from the ash of rice husks is more energy-efficient when used in manufacturing than that obtained from conventional materials such as quartz sand.

Plant-based oils – such as rapeseed oil and resins based on residual materials from the paper and wood industries – already offer an alternative to crude-oil-based fillers in Continental's tires. Only oils that meet technical quality standards and are not suitable for consumption are used. Oils and resins allow for flexibility in terms of tire compounds and so improve the material’s grip.

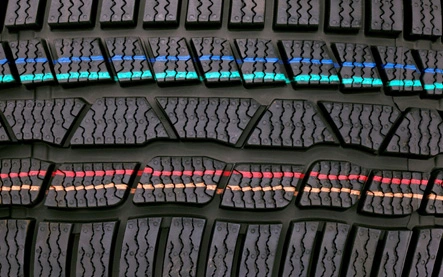

In addition to pyrolysis, Continental is also making use of mechanical processing of end-of-life tires. Rubber, steel and textile cord in particular are separated, in a highly sophisticated process, from one another. The rubber is then prepared for re-use as part of new rubber compounds.

Continental has a long history of working consistently to introduce end-of-life tires into the circular economy to conserve resources and the environment. A material known as “Conti-Reclaim” has been obtained as part of the truck tire retreading process at the company’s plant in Stöcken in Hanover since 2013. It has been used in tire production at Continental for years. To expand the range of applications for the recycled rubber and optimize the properties for the various fields of application, Continental uses not only “Conti-Reclaim” but also recycled rubber from other suppliers.

For example, Continental is working with partners to obtain high-quality polyester yarn for its tires from recycled PET bottles. PET bottles often end up in incinerators or landfills otherwise. With its ContiRe.Tex technology, the tire manufacturer has developed a more energy-efficient and eco-friendly alternative that allows it to reuse between nine and fifteen plastic bottles for each tire, depending on the tire size. The recycled PET has already replaced conventional polyester in the structures of some tire casing. The PET bottles used are sourced exclusively from regions where there is no closed recycling loop.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt

.jpg)