Conveyor belts and their conveying systems are important equipment components required for the transportation of various bulk materials such as ore, coal, and grain during the mining and production process. With the improvement of automation and the remoteness of mines, the use of conveyor belts is currently the safest, most efficient and economical way to continuously transport materials under complex working conditions, and has become an important guarantee for promoting the development of key national economic fields. The most basic structural form of a conveyor belt includes a middle belt core layer and upper and lower cover rubber layers. The belt core layer, as the skeleton material of the conveyor belt, bears almost all the load of the conveyor belt. Therefore, the skeleton material is crucial to the performance of the conveyor belt. With the development of conveyor belts towards long distances, high belt speeds, large transport volumes, energy conservation and environmental protection, the skeleton material of conveyor belts has also developed from ordinary fibers and ordinary steel wire ropes to special fibers and high-strength steel wire ropes. Many papers have introduced the skeleton materials for conveyor belts. This article reviews the current status of skeleton materials for conveyor belts and their optimal design.

1.Current status of skeleton materials for conveyor belts.

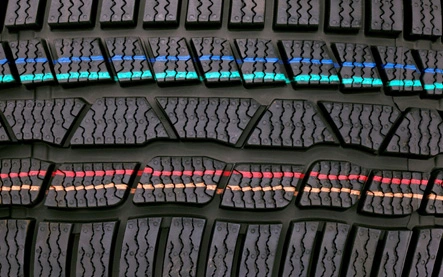

Structure of fabric skeleton material The fiber material needs to be woven into a certain fabric structure to give full play to the mechanical properties of the material. Under the condition of conveying materials such as ore with impact, 80% of the conveyor belt damage is caused by damage to the skeleton material. Therefore, in addition to the type of skeleton material used, the weaving structure of the skeleton material also has a very important influence on the conveyor belt. The fabric structure used for conveyor belts usually includes: plain weave structure, integral fabric structure and straight warp and straight weft structure.

2. Optimal design of skeleton materials

As the material conveying distance continues to increase, the working conditions of the materials become more complex, and the requirements for heat resistance, flame retardancy, impact resistance, antistatic, and anti-adhesion are high. At the same time, the conveyor belt has a higher lifting height, a longer conveying distance, and an increased degree of unattended automation. The corresponding strength, life, and fatigue resistance of the skeleton material are also required to be increased accordingly. The overall development trend of the conveyor belt is to reduce weight and improve energy-saving performance; reduce the core layer of the belt, and improve the strength utilization rate of the skeleton material. Based on the above development trends, the skeleton material for the conveyor belt is modified and optimized.

In summary, the current fabric core skeleton materials of conveyor belts are mainly nylon fiber and polyester fiber; aramid is currently mainly used in coal mines due to price factors. (1) In terms of the structure of fabric skeleton materials, plain weave structure is still the main structural form of the current layered conveyor belts, but the straight warp and straight weft structure is a development direction of the conveyor belt fabric structure due to its advantages such as high strength utilization and low buckling strength. In terms of the optimization design of skeleton materials, material body modification, skeleton structure optimization design and the development of new skeleton materials are three feasible optimization design directions. (2) Ultra-high molecular weight polyethylene fiber is expected to become a new generation of fabric core skeleton material due to its excellent comprehensive performance and high performance-price ratio. The existing steel wire rope core skeleton material is relatively mature, and a feasible performance optimization method is to use structural design to make up for its poor tear resistance. (3) Conveyor belt cores are generally considered to be two major categories - fabric belts and wire rope belts. In fact, this is just a classification method for the convenience of the industry and customers. The core of the conveyor belt is to meet the customer's material transportation needs. With this goal in mind, there is no need to be particularly obsessed with which classification method (fabric/wire rope) to choose for the belt core. It only needs to meet the use requirements of the conveyor belt.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt