Growth in the automotive industry in Asia Pacific is boosting the EPDM rubber market in this region. EPDM rubber is also used as a substitute for thermoplastic olefins (TPO) and thermoplastic vulcanizates (TPV) in the plastic manufacturing industry. Technology advancements in manufacturing plastics also help in the growth of the EPDM rubber market. Growth in the automotive industry in India, China, South Korea, Japan, and Thailand further contributes to the EPDM rubber market in Asia Pacific.

Synthetic rubber is produced from crude oil and natural gas. It is mainly produced by the polymerization of monomers. Synthetic rubber has many benefits over natural rubber, such as better resistance to oil and temperature. It is used in a wide range of applications, but its major application is in tires. The growing tire industry is one of the key factors in the growth of the synthetic rubber market. The Asia Pacific region is driving the demand for synthetic rubber in the tire and non-tire automotive applications due to the region’s growing automotive industry. Synthetic rubber has properties such as resistance to oil, grease, and ozone, good impact strength, flexibility at low temperatures, and good resilience, making it suitable for automotive applications. This elastomer has elastic properties and is joined by chemical bonds to form a crosslinked structure.

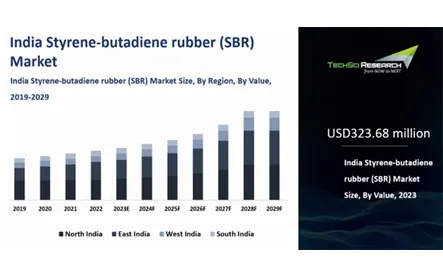

Synthetic rubber is popular because of its easy moldability at room temperatures, such as plastics and elastomers. Owing to its properties, such as heat stability, smoothness, wear resistance, and scratch resistance, it is used in various end-use industries. There are six main types of synthetic rubber, namely, styrene-butadiene rubber (SBR), styrenic block copolymer (SBC), ethylene propylene diene rubber (EPDM), butyl rubber (IIR), and acrylonitrile-butadiene rubber (NBR). According to MarketsandMarkets the market size of synthetic rubber is expected to reach USD 28,923.0 million by 2027. The SBR type accounted for the largest market share of 31.6% in 2021. The tire segment is estimated to be the largest application of synthetic rubber during the forecast period, followed by the automotive (non-tire) segment in terms of volume.

Synthetic rubber increases the lifespan of tires with reduced rolling of tires to increase the fuel efficiency of vehicles. It has performance characteristics such as stiffness and abrasion resistance, making synthetic rubber suitable for replacing metal, glass, and wood parts used in automotive and industrial applications.The synthetic rubber market has witnessed moderate growth in the past few years, which is primarily attributed to the increasing demand for highly efficient and lightweight materials in the automotive, building & construction, footwear, and other industries. Synthetic rubber is preferred over conventional metals in the automobile industry to increase efficiency by reducing fuel consumption and carbon emissions and making engines compact. On the other hand, instability in international crude oil prices and fluctuations in labor & energy costs result in price volatility, which poses a challenge to the growth of the synthetic rubber market. The major end-use markets that consume synthetic rubber are automotive, engineering, footwear, textile, and consumer goods, among others.

Synthetic rubber is manufactured by the polymerization of monomers. Typically, styrene and butadiene are polymerized to produce styrene butadiene rubber (SBR) and polybutadiene rubber (BR). Subsequent developments have introduced other monomers, such as ethylene and propylene, which are used in the production of EPDM. The other types of synthetic rubber include isobutylene isoprene Rubber (IIR); it can be modified with halogen atoms such as chlorine or bromine to produce chlorobutyl and bromo butyl, together known as halo-butyls and nitrile (acrylonitrile butadiene). There is also a synthetic version of natural rubber known as polyisoprene or isoprene rubber.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt