Polyurethane and aramid fiber timing belts combine the elasticity and wear resistance of polyurethane with the high strength and high-temperature resistance of aramid fiber, making them suitable for transmission systems operating under high-temperature conditions. The high-temperature resistance of aramid fiber (long-term operating temperature up to 200°C) significantly improves the heat resistance of timing belts, while the polyurethane matrix can also remain stable at high temperatures through modification. This article analyzes its high-temperature resistance in detail from four aspects: material properties, high-temperature resistance mechanisms, influencing factors, and optimization methods.

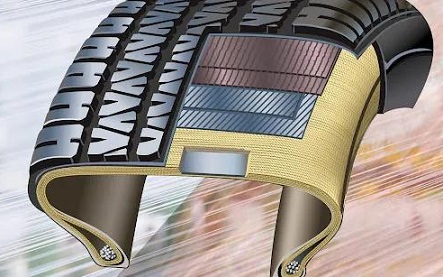

Polyurethane Matrix Properties: The long-term operating temperature range of ordinary polyurethane is -40°C to 80°C, and it can withstand temperatures up to 100°C for short periods. Through modification (such as the addition of heat stabilizers), polyurethane's temperature resistance can be increased to 120°C-150°C. 2. Aramid Fiber Properties: Aramid fibers (such as Kevlar) have excellent high-temperature resistance, with long-term operating temperatures up to 200°C and short-term temperatures up to 250°C. Their thermal decomposition temperature exceeds 500°C, yet they maintain high strength (tensile strength approximately 3000 MPa) and high modulus (approximately 70 GPa) at high temperatures. 3. High-Temperature Resistance Mechanism: Aramid fibers, as the reinforcement layer, maintain high mechanical properties at high temperatures and bear the primary load. The modified polyurethane matrix utilizes heat stabilizers and a cross-linked structure to delay softening and decomposition at high temperatures.

Key Factors Affecting High-Temperature Performance

Polyurethane Matrix Temperature Resistance

Conventional polyurethane softens easily at high temperatures and requires modification to improve its temperature resistance.

Adding heat stabilizers (such as antioxidants and UV absorbers) can delay high-temperature aging.

2. Aramid Fiber Content and Distribution

Increasing the aramid fiber content improves the overall temperature resistance of the synchronous belt, but reduces flexibility.

Uniform fiber distribution helps improve load transfer efficiency at high temperatures.

3. Interfacial Bonding Strength

Poor interfacial bonding at high temperatures can lead to delamination and failure, requiring optimization through surface treatment (such as plasma treatment).

4. Operating Conditions

Oxidation, moisture, and chemical agents in high-temperature environments can accelerate material aging, requiring comprehensive consideration of protective measures.

1. Polyurethane Matrix Modification: Add thermal stabilizers and crosslinkers to improve the heat resistance and thermal stability of polyurethane. 2. Optimize Fiber Content and Distribution: Rationally design the aramid fiber content (typically 30%-40%) to ensure its reinforcing effect at high temperatures. 3. Improve Interface Bonding: Surface treat the aramid fiber (e.g., with a silane coupling agent) to enhance the interfacial bonding strength with polyurethane. 4. Application Scenarios: ○ High-Temperature Drive Systems: Used in metallurgical equipment and drying equipment to withstand high-temperature environments. ○ High-Load Drives: Used in construction machinery and mining equipment to withstand high-temperature and high-load conditions. ○ High-Speed Drives: Used in textile machinery and printing equipment to maintain high-speed operation under high temperatures.

Summary: Polyurethane-aramid fiber timing belts significantly enhance high-temperature performance by leveraging the high-temperature stability of aramid fibers and the heat resistance of modified polyurethane. By optimizing fiber content, interfacial bonding, and matrix modification, their stability and service life in high-temperature environments can be further enhanced. Polyurethane-aramid fiber timing belts demonstrate exceptional performance in high-temperature transmission systems, high-load transmissions, and high-speed transmissions, providing a reliable solution for industrial transmissions operating under high-temperature conditions.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt