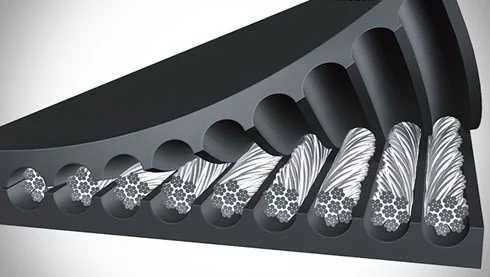

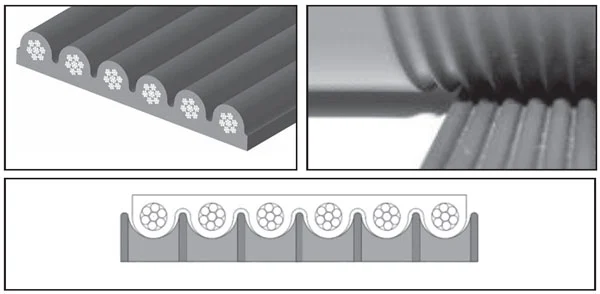

Steel Wire Rope is commonly comprised of wire core and strand, which is made using various types of steel including galvanized, coated and non coated. The steel wire ropes are also named as wire cables and steel wire , which are featured with high strength , flexibility , abrasion resistance, corrosion resistance and rotation resistance. This makes them well suited for varieties of uses such as pulling, fixing and bearing in the rubber industry, marine, architectural ,mining and etc. YUSHENG are mainly producing and supplying Galvanized Steel Wire Rope and Brass coated steel wire rope.

YUSHENG's Steel Wire Rope are widely used for steel wire rope rubber conveyor belt, timing belt , elevator belt and agriculture, engineering rubber track(crawler belt) and other rubber industry.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.