Rubber accelerators are chemicals used to speed up the vulcanization process of rubber. This process makes untreated natural rubber latex suitable for use in the manufacture of many rubber products. And there're various types of rubber accelerators available at Yusheng Enterprise.

Rubber accelerator is a chemical that is applied to a rubber compound to speed up vulcanization and allow vulcanization to occur at lower temperatures and with greater efficiency. Accelerator also reduces the amount of sulfur required for vulcanization, increasing the 'aged' qualities of the rubber vulcanizate.

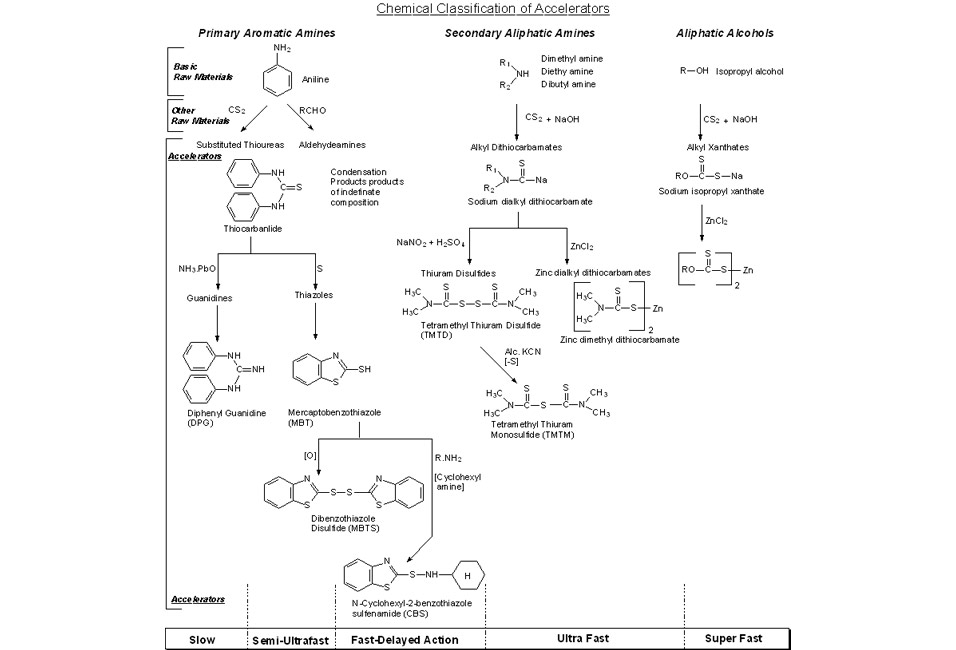

These rubber additives are further subdivided into Primary and Secondary accelerators based on their involvement in a certain compound.

Thiazoles and Sulfenamide accelerators, in general, play the role of Primary Accelerators due to their properties such as good processing safety, a broad vulcanization plateau, optimal cross link density, and desired reversion latency. Most rubber compounds employ 0.5 to 1.5 phr doses of Primary Accelerators.

Secondary accelerators, such as guanidines, thiurams, and dithiocarbamates, are employed to activate the primary accelerators. Secondary accelerators significantly boost vulcanization speed at the expense of scorch safety. Secondary accelerator dosages are typically 10-40% of the primary accelerator dosage.

Accelerators are chemical additives used in rubber compounding to speed up the vulcanization process. They promote the formation of cross-links between rubber polymer chains, enhancing the mechanical properties of the final product. Common sulfur accelerators include Mercaptobenzothiazole (MBT), N-Cyclohexyl-2-benzothiazolesulfenamide (CBS accelerator), and Dibenzothiazyl disulfide (MBTS accelerator). Accelerator selection depends on the rubber type, desired properties, and processing conditions. Proper control of accelerator levels is crucial to prevent over-curing or scorching, ensuring optimal performance and durability in the cured rubber.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.