Chafer fabric, a specialized textile material employed in tire manufacturing, plays a crucial role in reinforcing and protecting the sidewalls of tires. As an essential component in the automotive industry, chafer fabric ensures optimal tire performance and safety. In this article, we delve deeper into the characteristics, uses, and future trends of chafer fabric.

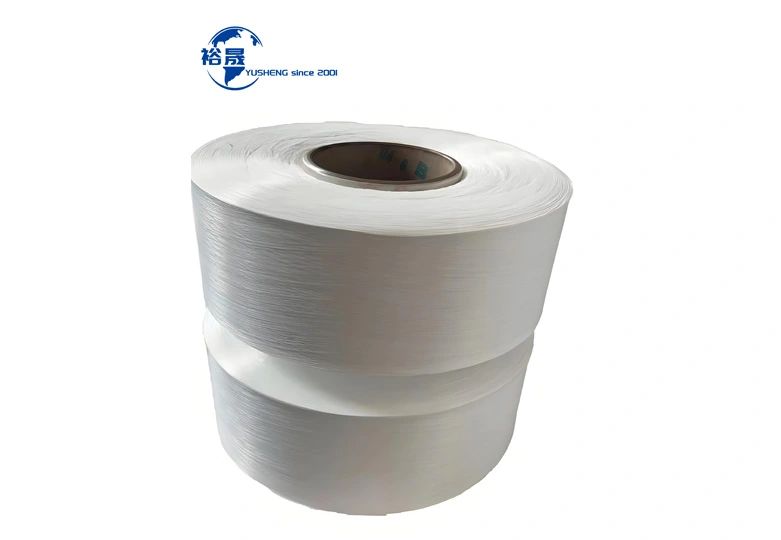

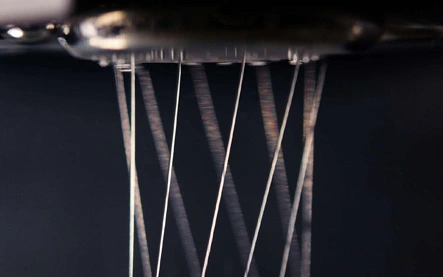

Chafer fabric, aptly named for its role as a buffer or cushion between the tire and the rim, is crafted from synthetic fibers like polyester or nylon. These fibers, chosen for their robustness and durability, undergo a meticulous weaving process to create a resilient fabric. The weaving pattern, tailored to desired properties such as strength, flexibility, and abrasion resistance, forms the basis of chafer fabric's effectiveness.

The primary function of chafer fabric is to provide reinforcement to tire sidewalls, counteracting the substantial stress and wear they endure during operation. This reinforcement prevents deformation, bulging, and separation of tire layers, particularly crucial during high-speed maneuvers, cornering, and braking. The added layer of strength enhances structural integrity, minimizing the risk of premature wear and damage.

Chafer fabric serves as a protective layer, preventing frictional forces and heat generated during tire rotation. This protective barrier reduces the risk of premature wear, ensuring the tire's longevity and sustained performance.

Beyond reinforcement, chafer fabric acts as a safeguard, preventing the tire from slipping or shifting on the rim. This feature is vital in avoiding misalignment, ensuring proper fitment, and enhancing overall safety and stability, thereby mitigating potential accidents.

The production of chafer fabric involves rigorous quality control measures, adhering to industry standards and certifications to meet the automotive sector's strict requirements. Manufacturers conduct extensive testing, including assessments of tensile strength, abrasion resistance, and heat resistance, ensuring the fabric's consistent performance, durability, and reliability.

With the automotive industry's evolving focus on performance, efficiency, and safety, the demand for high-quality chafer fabric is expected to rise. Manufacturers are investing in research and development to further enhance chafer fabric properties, exploring avenues to reduce weight and improve sustainability. The exploration of alternative materials and manufacturing processes aligns with environmental regulations, fostering greater resource efficiency.

In conclusion, chafer fabric stands as a linchpin in tire manufacturing, providing essential reinforcement and protection to tire sidewalls. As tire manufacturers and automotive suppliers continue to prioritize performance and safety, chafer fabric remains a key contributor to the quality and reliability of their products. The collaboration between major tire manufacturers and specialized textile producers ensures the continued evolution of chafer fabric, meeting the dynamic demands of the automotive industry.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt