Polyamide fiber, commonly known as nylon, is one of the earliest synthetic fibers to be industrially produced in the world. Its molecular backbone is connected by amide bonds (-NHCO-), which form the basic structure of this large family. The polyamide family is rich in varieties, with aliphatic polyamides being the most common. These have predominantly aliphatic molecular chains, such as nylon 6 (PA6), nylon 66 (PA66), and nylon 56 (PA56). The naming convention for aliphatic polyamides represents the number of carbon atoms in their monomers: ● Diamine/diacid condensation: Varieties formed by the condensation of diamines and diacids (such as nylon 66). The first digit in the name indicates the number of carbon atoms in the diamine (e.g., hexamethylenediamine is 6), and the second digit indicates the number of carbon atoms in the diacid (e.g., adipic acid is 6).

● Amino acid/lactam polymerization: Varieties formed by amino acid condensation polymerization (such as nylon 11) or lactam ring-opening polymerization (such as nylon 6). The naming number is the number of carbon atoms in the amino acid or lactam.

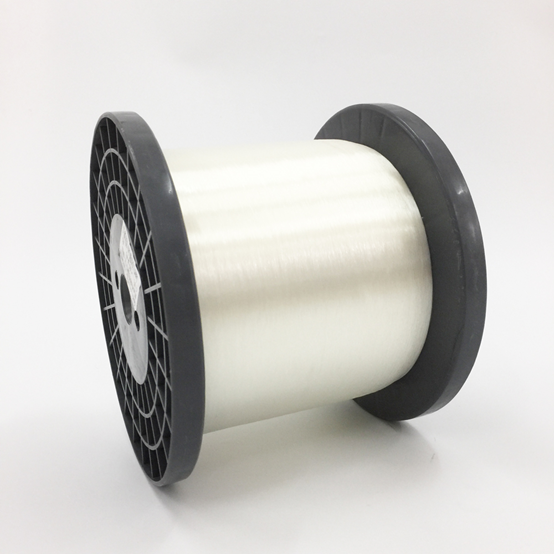

● Nylon 6 (PA6) Nylon 6 was developed by Paul Schlack at IG Farben in 1938 as a response to DuPont's Nylon 66. Its creation aimed to circumvent patent restrictions and achieve rapid commercialization, becoming a crucial material for the textile and plastics industries after World War II. Nylon 6 is a homopolymer with repeating units of [NH−(CH₂)₅−CO]ₙ, derived from the single monomer ε-caprolactam (a cyclic amide). Its molecular chains can form non-parallel hydrogen-bonded sheets, giving it excellent elasticity and flexibility. Nylon 6 is produced through the ring-opening polymerization of caprolactam. In the reaction, caprolactam undergoes ring-opening in the presence of water upon heating, forming aminocaproic acid, which is then further polymerized into long chains. Compared to the condensation polymerization of nylon 66, this process is simpler and less expensive, thus having wider applications. It possesses excellent mechanical properties, including high impact resistance, good elasticity, and rapid moisture absorption. It has good insulation, chemical resistance, and abrasion resistance, but its heat resistance and rigidity are slightly lower than those of Nylon 66. It appears translucent to milky white, with better elastic recovery, but relatively lower colorfastness.

● Nylon 66 (PA66) Nylon 66 was the first nylon, synthesized by Wallace H. Carothers at DuPont in 1935. It was first used in toothbrushes in 1938, entered the stocking market in 1940, and saw a surge in production during World War II due to demand for parachutes and military fabrics. DuPont maintained a long-term patent monopoly on it. The repeating unit of Nylon 66 is (−C(O)(CH₂)₄C(O)−NH(CH₂)₆NH−)ₙ, composed of hexamethylenediamine (6 C) and adipic acid (6 C). This alternating (ABAB) structure can form parallel-chain hydrogen-bonded crystalline regions, enhancing the material's strength and crystallinity. It is produced through a condensation reaction: hexamethylenediamine reacts with adipic acid to form a nylon salt, which, after purification and crystallization, is polymerized at approximately 285 °C, releasing water. This process requires precise metering and temperature control, making it more complex than nylon 6. It possesses extremely high mechanical strength, rigidity, heat resistance, abrasion resistance (up to 60,000 cycles), and creep resistance. Its weather resistance, sunlight resistance, and color fastness are superior to nylon 6, but its impact resistance and hygroscopicity are lower. It is a good insulator when dry, but its properties change with increasing humidity.

● Nylon 56 (PA56) Nylon 56 (PA56) is a novel bio-based polyamide developed in recent years, with industrial breakthroughs achieved by companies such as China's Kaisai Biotechnology. Its key monomer, 1,5-pentanediamine, can be obtained through lysine fermentation, achieving large-scale production in 2013. Nylon 56 is formed by the condensation polymerization of pentanediamine (5C) and adipic acid (6C), belonging to the odd-even binary polyamide category. Its synthesis employs a melt polycondensation method: a salt is first formed, then a pressurized reaction is carried out at 220–270 °C, followed by depressurization to increase viscosity. This process is environmentally friendly, with low energy consumption and minimal pollution, reducing the use of non-renewable resources by approximately 50% compared to nylon 66. It exhibits higher moisture absorption than nylon 66, excellent dyeability and softness, and a more comfortable hand feel. It also demonstrates excellent thermal stability, with a 5% weight loss at approximately 340 °C. Some studies indicate that its acid resistance is superior to both nylon 6 and nylon 66. While its overall performance is close to that of nylon 66, it offers advantages in fabric comfort and environmental sustainability.

Core Performance

● Moisture Absorption and Dyeability: Both PA6 and PA66 have good affinity for acidic or reactive dyes, with a standard moisture regain of approximately 3%. PA56 has a higher moisture regain, and its moisture absorption and wicking properties are close to those of cotton fibers. It also has a faster dyeing rate, higher dyeing uniformity, and can be dyed below 100℃, saving approximately 10–15% more energy than PA66.

● Chemical Resistance: All three are sensitive to strong acids and have good alkali resistance. PA56, due to its odd-carbon structure, has a more flexible molecular chain, resulting in only about 5% strength loss after 100 hours of immersion in a pH 4 environment. Its acid resistance is about 30% better than PA6/66.

● Weather Resistance and Aging Resistance: PA66 has a dense structure, offering the best stain resistance and impermeability; PA6 is slightly inferior. PA56, due to its high chain segment flexibility and good hydrogen bond recovery, has superior aging resistance and UV resistance.

The core properties of PA6, PA66, and PA56 represent three stages in the development of nylon materials:

Nylon 6: Versatile, soft to the touch, and excellent dyeability; widely used in everyday textiles.

Nylon 66: Offers superior strength, stiffness, and thermal stability; the preferred choice for industrial and technical applications.

Nylon 56: Represents a new generation of bio-based nylon, combining performance with sustainability, with great potential in environmentally friendly textiles and engineering materials.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt