Both natural rubber and synthetic rubber hold an important place within the rubber industry, both in high demand by manufacturers. The difference between natural and synthetic rubber (in terms of how they're made and their properties) makes both types of rubber useful for different applications. In this post, we look at natural rubber vs synthetic rubber, explaining the differences and the pros and cons of both.

Natural rubber is typically sourced from Hevea brasiliensis or the Pará rubber tree. This native Brazilian plant is now cultivated in South and Southeast Asian countries like Thailand, Indonesia, Malaysia, India and Vietnam. Other plants can be used as a source for natural rubber, including the Panama rubber tree, rubber fig and the common dandelion. However, Hevea brasiliensis is the favoured source for commercial use by many. Latex is obtained from the plant, and that is what is used to make rubber. Natural rubber is an elastomer, meaning it is an elastic substance and can recover back to its original shape when stretched. The most common commercial use of natural rubber is in tyres, spanning various industries, including automotive and aerospace.

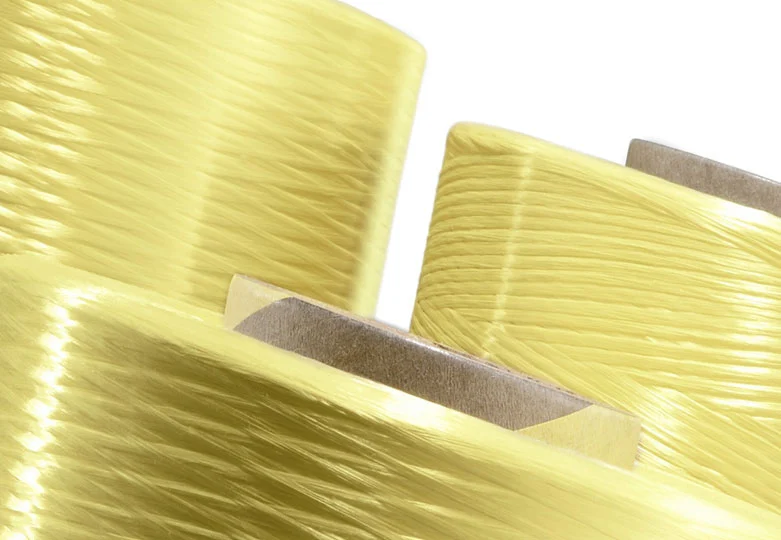

Synthetic rubber can be produced artificially via the polymerisation of monomers into polymers. This can be done in two ways, either by solution polymerisation or emulsion polymerisation. There are many different types of synthetic rubber made up of different monomers before the polymerisation process. Due to the polymers being artificially produced, synthetic rubber can have different properties and have many applications. The application of synthetic rubber can be seen all around us; some examples include wetsuits, balloons, PPE, the soles of shoes and rubber bands.

The difference between natural and synthetic rubber can be seen in the way it is produced, meaning that the properties of each are different. Is one better than the other, though? Well, each one is more suited to certain types of application than the other. Generally, synthetic rubber is better than natural rubber in terms of temperature resistance, ageing resistance and resistance to abrasion. Synthetic rubber also tends to be cheaper to produce.

On the other hand, natural rubber is known for its properties as a strong, flexible and heat-resistant material used to create latex products. Ultimately, which type of rubber is "better" depends on its application. For example, although additives can be added to natural rubber to improve saltwater resistance, neoprene displays better resistance and tends to be preferred for marine applications.

The following table highlights that although synthetic rubbers can be produced to give favourable properties in most aspects, natural rubber is a good "all-rounder" and can be further

Comparison of Properties – Natural Rubber vs Synthetic Rubber

Natural rubber | Synthetic range | |

Hardness available (°Shore A) | 25-95 | 10-95 |

Temperature resistance (°C) | -40 to 80 | -70 to 180 |

Short-time peak temp (°C) | 100 | 100 to 350 |

Tensile Strength (N/mm2) | 25 | 8 to 30 |

Tensile elongation (%) | 800 | 150 to 800 |

Abrasion | Good | Moderate to excellent |

Flexibility | Excellent | Bad to excellent |

Resistance to light | Bad | Bad to Excellent |

Resistance to oxidising | Moderate | Moderate to excellent |

Resistance to ozone | Moderate | Moderate to excellent |

Resistance to wear/tear | Very good | Bad to excellent |

Weathering effect | Good | Moderate to excellent |

Resistance to petrol | Unsuitable | Unsuitable to excellent |

Resistance to foodstuffs | Suitable | Unsuitable to excellent |

Resistance to oils and greases | Unsuitable | Unsuitable to excellent |

Resistance to water | Good | Unsuitable to excellent |

Natural and synthetic rubber can be substituted. However, the difference in each limits the degree to which they can be direct substitutes, which means that the market for each is not that closely related, hence the price differences. More commonly, natural and synthetic rubbers are used as complementary goods in the production of tyres. In general, the demand and the price for both types of rubber grow as the automotive sector does.

The price difference between natural and synthetic rubber is due to both demand-side factors; use and production and supply-side factors, including the prices of raw materials and agricultural constraints. However, the price of rubber is primarily affected by supply-side factors, causing a lot of volatility, particularly in natural rubber.

The table below indicates the demand- and supply-side factors that cause differences in natural vs synthetic rubber price

Demand-Side Factors (Affecting Price) | Supply-Side Factors (Affecting Price) | |

Natural Rubber | · Production that requires strength, flexibility, heat resistance, resistance to tearing | 5-7 year lag between planting and production Weather Price and availability of seedlings Cost of labor Availability and cost of land Profitability of rubber compared to other crops |

Synthetic Rubber | · Production that requires abrasion resistance, heat and ageing resistance, elasticity, resistance to grease and oil | ·Price of inputs like crude oil, crude petroleum and natural gas |

Overall, it’s easy to see that it depends entirely on the application as to which is the best type of rubber for the job when it comes to natural vs synthetic rubber. At GMT, we have developed our own process using raw rubber and an automated mixing system to ensure that our customers’ requirements are met. From anti-vibration mounts to resilient wheels, we always produce the highest quality anti-vibration rubber products.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt