Para-aramid is a high-performance synthetic fiber with ultra-high strength, ultra-high modulus and high temperature resistance, suitable for extreme working conditions such as high pressure and corrosion. Recently, sinapara® para-aramid, independently developed and produced by Sinochem International, a subsidiary of Sinochem, has been innovatively applied to the field of thermoplastic pipe (RTP pipe) reinforcement, helping to achieve low-cost and long-term operation and maintenance of offshore oil pipelines, and providing a safer and more efficient solution for offshore oil field development.

Innovative application, innovative deep-sea oil and gas transportation solutions

After the offshore oil field oil pipeline has been in service for a certain number of years, it will have problems such as structural aging, corrosion and damage, and needs regular repair and maintenance. However, some submarine oil pipelines have complex layouts, and traditional operation and maintenance methods such as punch-in repair, lining hose repair, and in-situ internal coating are difficult to implement.

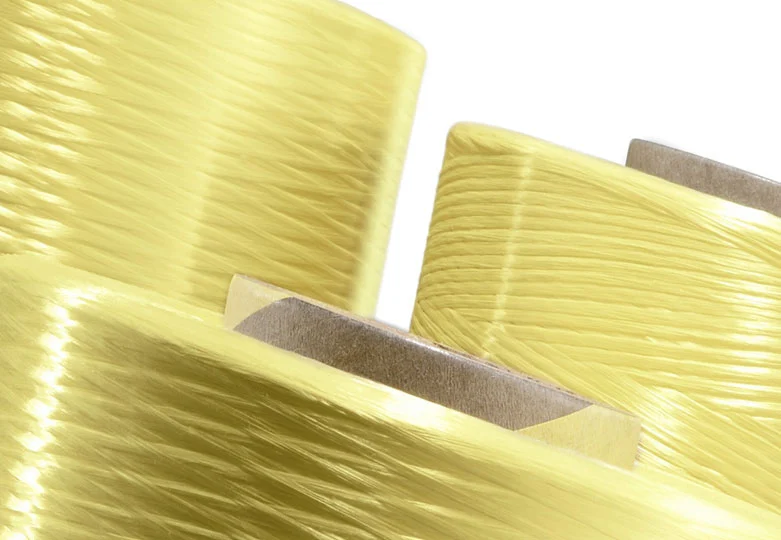

In response to this pain point, China used Sinochem International's sinapara® para-aramid SF6800 high-strength product to reinforce thermoplastic plastic pipes (RTP pipes) for the first time, and trial-produced high-performance composite flexible pipeline products including anti-corrosion inner layer, para-aramid winding reinforcement layer and wear-resistant outer layer.

This flexible pipeline can be used for internal insertion operations on marine oil pipelines (that is, inserting a new layer of RTP pipe inside the pipeline to be repaired, using the principle of heat shrinkage to make the new pipe and the old pipe tightly combined, thereby restoring the sealing and strength of the pipeline), perfectly solving the problem of deep-sea pipeline repair and innovating deep-sea oil and gas transportation solutions.

As one of the three most high-performance fiber materials recognized worldwide, para-aramid has the advantages of high strength, high modulus, and corrosion resistance.

In the para-aramid reinforced thermoplastic pipe, the para-aramid winding reinforcement layer is the load-bearing component that can absorb all stress caused by internal pressure. In addition, para-aramid also gives thermoplastic pipes many advantages.

As one of the three most high-performance fiber materials recognized worldwide, para-aramid has the advantages of high strength, high modulus, and corrosion resistance.

In the para-aramid reinforced thermoplastic pipe, the para-aramid winding reinforcement layer is the load-bearing component that can absorb all stress caused by internal pressure. In addition, para-aramid also gives thermoplastic pipes many advantages.

Highlight 1: Significant performance improvement

★ Compared with traditional steel pipes and FRP pipes, it has the advantages of high impact resistance, hydrolysis resistance, acid and alkali corrosion resistance and stress corrosion resistance.

★ The weight is only 30%-50% of that of metal pipes.

★ It can be used for a long time in an environment up to 200℃.

★ It is suitable for conveying corrosive oil and gas with high salt content, high carbon dioxide or high hydrogen sulfide content.

Highlight 2: Obvious cost advantage

★ The operation and maintenance installation efficiency is 5 times that of traditional operation forms, and the laying cost is reduced by nearly 30%.

★ The service life of the pipe reaches 25 years, far exceeding the performance requirements of customers.

★ One of the best economical pipes for deep-sea and deep-earth oil and gas transportation in the future.

Highlight 3: Safer and more reliable

★ The continuous length of a single pipe can reach thousands of meters, which is more adaptable to various complex laying operation scenarios than hard pipes.

★ There are very few operation joints, which greatly reduces the risk of pipeline leakage.

As a high-tech enterprise focusing on the research and production of aramid products, Sinochem International has an annual production capacity of 8,000 tons of high-modulus, high-strength para-aramid, and its product quality has reached the international advanced level.

Sinochem International has the ability to operate products across the entire industry chain, family and life cycle. It has completed the LCA assessment (Life Cycle Assessment, which evaluates the overall environmental impact of the entire product process) and product carbon footprint verification for para-aramid filament products, and obtained certification from the third-party authoritative certification agency SGS based on ISO 14040, ISO 14044 and ISO 14067 standards. It can provide customers with accurate and reliable product carbon emission data, and strongly support the carbon management and sustainable development of customers and downstream industries.

At present, Sinochem International's three categories of products, ordinary, high-strength and high-modulus, have entered all mature application markets. Its para-aramid products have a leading domestic market share in the fields of safety protection, optical cable reinforcement, etc., and have also achieved mass supply in the fields of tires, brake pads, etc. At the same time, Sinochem International has also launched a number of product application solutions such as para-aramid ultrafiltration membranes, para-aramid rubber skeletons, and para-aramid mooring ropes, continuously strengthening application development and services, and continuously opening up incremental market space.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt