Due to global climate change and accelerated urbanization, earthquakes occur frequently, seriously threatening the safety of building structures. According to statistics, the global economic losses caused by earthquakes since the beginning of the 20th century have exceeded one trillion US dollars, and the number of victims is countless. Therefore, enhancing the seismic performance of building structures and reducing the damage caused by earthquakes to human society has become a hot topic in the global engineering community [1]. As a new type of seismic reinforcement material, high-strength aramid fiber fabric has the characteristics of being lightweight, high-strength, durable, and stable, and has great potential for application and development in the field of building reinforcement. It has the advantages of reducing structural weight and improving structural safety, and can enhance the seismic resistance of existing buildings, extend their service life, reduce costs, and conform to the concept of sustainable development [2-3]. Therefore, studying the application and performance of high-strength aramid fiber fabric as a seismic reinforcement material is of great practical significance for promoting the development of building technology, especially building safety technology, and protecting the safety and property of the general public.

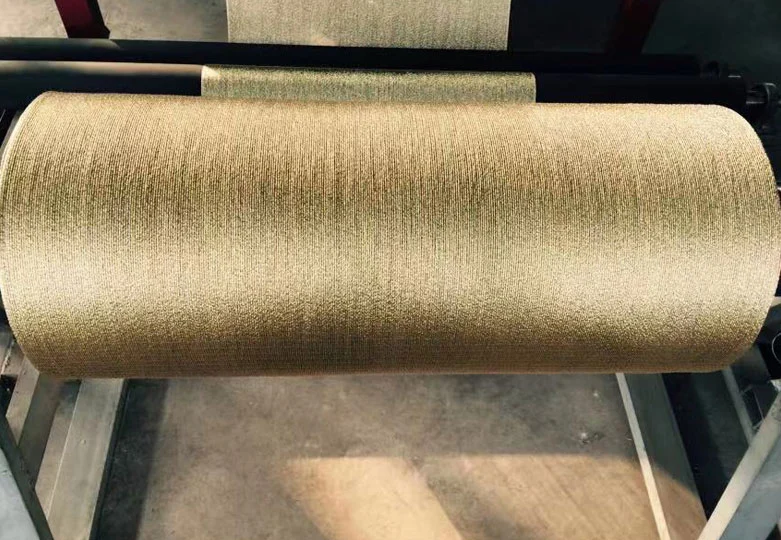

1.1 Characteristics of Aramid Fiber Materials High-strength aramid fiber fabrics have performance advantages and usage characteristics, and have potential application prospects in seismic reinforcement. Aramid fiber, also known as aromatic polyamide fiber, is composed of benzene rings and imino groups, and has the characteristics of high strength, high modulus, low density, heat resistance, and chemical resistance[4]. The tensile strength of Kevlar fiber produced by DuPont is 2800MPa, which is about 5 times that of steel, while its density is only 1/5 of that of steel. Its high strength and light weight characteristics are beneficial to reducing the load on the building structure in seismic reinforcement and providing support. Aramid fiber has significant fatigue resistance and impact resistance characteristics. In the process of seismic reinforcement, it will be subjected to repeated loads and strong vibration impacts. Therefore, fiber-based impact reinforcement is very necessary. In actual seismic reinforcement projects, aramid fiber fabrics can be combined with concrete, steel, etc. to form a composite reinforcement structure. 1.2 Production Technology of High-Strength Aramid Fiber Fabrics The production technology of high-strength aramid fiber fabrics is currently the key technology used for seismic building reinforcement. Aramid fiber is known as the "super fiber of the 21st century" due to its excellent mechanical properties and high temperature resistance. Polymerization technology and spinning technology are key links in the production process of aramid fiber, which can have an important impact on fiber strength and modulus. The use of dry-jet wet spinning technology can significantly improve fiber strength and modulus. Heat setting process is a post-treatment process for fiber, which can improve fiber durability and stability[5]. In the production process of aramid fiber, the performance of finished aramid is generally controlled by adjusting parameters such as spinning speed, stretch ratio, and heat treatment temperature. Relevant literature points out that adjusting the spinning speed to 1000~2000m/min can obtain aramid fiber with tensile strength exceeding 3.5GPa. The choice of aramid fiber weaving method directly determines the mechanical properties of the fabric. In the field of seismic reinforcement, the tensile strength of aramid fiber fabric woven by multi-axial weaving method is 2.75~3.88kN, and the tear resistance is 22.00~37.00kN. Innovation and improvement of aramid fiber fabric production technology are the main driving forces to ensure the convenience and economy of building construction in the field of seismic reinforcement.

2.1 Development History of Seismic Strengthening Materials The emergence of high-strength aramid fiber fabric strengthening materials represents a revolution in strengthening technology. This type of material is a landmark product in the transition of strengthening materials from reinforced concrete to composite materials. Influenced by the 1994 Northridge earthquake in the United States and the 1995 Hanshin earthquake in Japan, the seismic resistance standards of building structures have been raised. Finding lighter, stronger, tougher, and more durable strengthening materials has become a focus for materials engineers and engineers. High-strength aramid fiber fabrics, with their excellent high strength, low density, corrosion resistance, and fatigue resistance, have been developed and applied in seismic strengthening materials. Related studies have found that the tensile strength of aramid fibers is 5-6 times higher than that of steel, while its mass is only 1/5 that of steel. Lighter building materials can effectively improve the seismic resistance of structures while reducing the building's self-weight. The durability and stability of aramid fiber fabrics have been experimentally verified, showing significant superiority over some traditional strengthening materials under extreme conditions. 2.2 Limitations of Existing Seismic Strengthening Technologies The shortcomings of existing seismic strengthening technologies are mainly reflected in the following aspects: First, traditional strengthening materials and methods have deficiencies in seismic performance. For example, reinforced concrete has extremely high strength and stiffness, but exhibits brittle failure characteristics under seismic loading. According to literature research, reinforced concrete structures generally exhibit shear failure under seismic loading, making them unsuitable for practical seismic strengthening applications. Second, while current strengthening methods can further improve the load-bearing capacity of the strengthened structure during strengthening, they are difficult to construct, require high technical skills from construction personnel, and are prone to aging and corrosion under harsh external conditions, limiting the durability of the strengthening effect. High-strength aramid fiber fabrics not only possess strong mechanical properties and ductility but also excellent durability and are extremely sensitive to earthquakes. Their tensile strength exceeds 2800 MPa, far exceeding the strength of ordinary steel bars, and they also have good fatigue resistance and corrosion resistance, maintaining long-term stability in harsh environments.

3.1 Mechanical Properties of High-Strength Aramid Fiber Fabrics High-strength aramid fiber fabrics possess excellent mechanical properties, making them suitable for earthquake-resistant building reinforcement systems. Aramid fiber is a man-made high-performance polymer fiber with tensile strength several times that of steel, yet weighs only 1/5 of steel. Under heavy loads, aramid fiber fabrics can fully utilize their high strength and load-bearing capacity, enhancing structural load-bearing capacity and effectively resisting earthquakes in building reinforcement projects. Furthermore, aramid fiber fabrics also exhibit strong impact resistance. During earthquakes, aramid fiber fabrics primarily absorb and disperse seismic energy due to their high strength and elastic modulus, protecting building structures from damage. 3.2 Durability and Stability of High-Strength Aramid Fiber Fabrics Durability and stability are crucial factors determining the anti-aging and long-term stability of aramid fiber fabrics. While aramid fiber fabrics are known for their excellent mechanical properties and resistance to acid and alkali corrosion, their durability and stability in practical applications still require further verification. Studies have shown that aramid fiber fabrics can retain more than 90% of their strength under ultraviolet irradiation, demonstrating their excellent lightfastness. Aramid fiber fabrics also exhibit relatively stable properties in acidic, neutral, and alkaline environments. After immersing in solutions with pH values of 3 to 11 for 72 hours, the strength loss rate of aramid fiber fabrics is less than 5%, demonstrating their continuous performance stability under different acidic and alkaline conditions.

4.1 Principles and Methods of Strengthening Design In the strengthening design of building structures, a precise evaluation system should be established for high-strength aramid fiber. This involves quantitatively analyzing and processing data parameters such as the structural bearing capacity characteristic value and damage index to determine performance benchmarks that meet the target strengthening requirements. Strict adherence to the "Code for Seismic Design of Buildings" is crucial, with a focus on improving structural coefficients and energy dissipation capacity design indicators. Simultaneously, an elastoplastic mechanical model should be established to ensure that the strengthened structure forms a multi-level energy dissipation mechanism under seismic loading, achieving plastic deformation and effectively avoiding brittle failure modes. The strengthening method should comprehensively consider the building's condition and the characteristics of the strengthening material. In the strengthening design process, high-strength aramid fiber fabrics are typically applied using either bonding or wrapping methods. Bonding can be used to strengthen bending members such as beams and columns. By bonding aramid fiber fabrics to the surface of the member, the bending and shear resistance of the member is significantly improved. Data shows that bonding aramid fiber fabrics to the surface of concrete beams can significantly improve the bending bearing capacity of concrete beams; measurements have shown that the bending bearing capacity can be increased by more than 30%. Wrapping can improve the axial bearing capacity and seismic performance of columns by wrapping aramid fiber fabrics around them. Furthermore, in practical applications, materials that are easy to construct, economical, and do not affect the building's functionality should be selected. It is also crucial to ensure that the reinforcement design guarantees the long-term structural integrity required for the building. 4.2 High-Strength Aramid Fiber Fabric Reinforcement Construction Technology The application of aramid fiber fabric reinforcement technology requires maximizing the material's inherent properties and tailoring its use to the specific conditions of the building and the requirements of the reinforcement materials. High-strength aramid fiber fabrics have a tensile strength exceeding 2800 MPa, far surpassing previous reinforcement materials, effectively withstanding earthquake damage and supporting the structure. In aramid fiber fabric reinforcement, an adhesive method is typically used, bonding the aramid fiber fabric to the structural surface to form a composite structure, thereby achieving seismic reinforcement.

5.1 Experimental Design and Material Preparation In the experimental and performance research of high-strength aramid fiber fabrics for earthquake-resistant building reinforcement, experimental design and material preparation are crucial. This study analyzed the mechanical properties of aramid fiber fabrics. Through tensile, compression, and shear tests on high-strength aramid fiber fabrics, data on tensile strength, elastic modulus, and elongation at break were accumulated. The results showed that high-strength aramid fiber fabrics have better earthquake-resistant reinforcement effects compared to traditional high-strength materials. Durability tests showed that aramid fiber fabrics exhibited good durability under harsh simulated environments (such as high temperature, high humidity, and ultraviolet radiation), with effects far superior to other reinforcement materials. Regarding material preparation, aramid fiber fabrics of different thicknesses and weaving densities were prepared to determine the influence of weaving density on the reinforcement effect. The results showed that a higher weaving density resulted in better reinforcement, but also higher costs. Therefore, the specific reinforcement project conditions and cost savings must be considered. 5.2 Performance Evaluation A comprehensive study on the application and performance of high-strength aramid fiber fabrics in seismic building reinforcement, along with analysis of experimental results, revealed that high-strength aramid fiber fabrics offer excellent reinforcement mechanical and durability properties. Their average tensile strength exceeds 2500 MPa, significantly higher than traditional steel reinforcement materials. Furthermore, experiments simulating different environments showed that the durability degradation rate of aramid fiber fabrics is only 5%, nearly 3% higher than that of steel reinforcement materials. In structural reinforcement design, implementing differentiated reinforcement schemes for different working conditions can achieve significant results. The column structure employs a circumferential wrapping technique with aramid fiber fabric, while the beam structure utilizes a U-shaped bonding process with aramid fibers. In seismic performance tests, the ultimate bearing capacity of the structure reinforced with high-strength aramid fiber fabric was significantly improved compared to the unreinforced component. Regarding crack control, crack propagation suppression reinforcement measures were adopted. Real-time testing showed that the maximum crack propagation width of the reinforced component was effectively controlled within the requirements of current seismic codes, indicating that the reinforcement measures significantly improve the ductility and deformation capacity of the component. In terms of construction process optimization, improved interface treatment significantly enhances the interfacial bonding performance between the aramid fiber fabric and the concrete matrix, ensuring that the composite material system can fully exert its synergistic effect.

Aramid fiber materials, with their excellent properties such as lightweight, high strength, corrosion resistance, and fatigue resistance, have opened up new avenues for seismic strengthening technology of building structures. Data shows that components strengthened with this material exhibit significantly improved flexural capacity, as well as increased ductility and energy dissipation coefficients, effectively improving the seismic performance of the structure. In engineering applications, wet bonding processes based on interface modification technology and prestressed winding construction methods achieve synergistic work between the strengthening layer and the original components while ensuring the functional integrity of the existing structure.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt