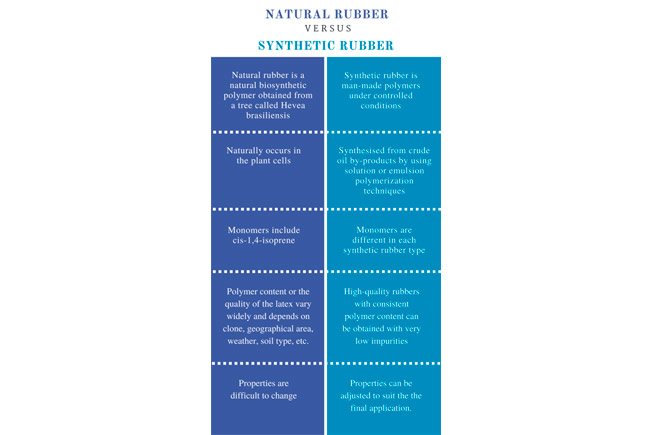

Natural and synthetic rubbers are two types of polymers with excellent properties that are widely in rubber industries for many rubber products and other industrial products. Each rubber type has its own chemical and physical properties depending on the nature of the monomer and chemical structure of the rubber.

The main difference between natural rubber and synthetic rubber is that natural rubber is a natural biosynthesis polymer obtained from a plant called Hevea brasiliensis, whereas synthetic rubbers are man-made polymers under controlled conditions.

Natural Rubber

Natural rubber can only grow in tropical climates and doesn’t age well. Most natural rubber is produced from the softwood Hevea brasiliensis tree, which is native to Brazil. However there are several other species of trees and shrubs from which natural rubber is sourced.

It has a high tensile strength, higher tear resistance, low odour, and is resistant to fatigue from wear such as chipping, cutting or tearing. It also has tack, which means it can adhere to itself as well as other materials. This is particularly the case for steel cord which makes it an excellent material for use in tires. Natural rubbers are also a very popular choice in the Subsea, Oil & Gas field particularly.

On the down side natural rubber has only moderate resistance to damage from exposure to heat, light and ozone. It also contains natural proteins which may cause allergic reactions when placed in contact with human skin for prolonged periods.

Synthetic Rubber

Synthetic rubber is artificially produced from polymers in different varieties to mimic the properties of natural rubber. So, for many countries, it is easier to use. In general, synthetic rubber including polybutadiene rubber and synthetic butyl rubber offers better resistance to abrasion than natural rubber, as well as superior resistance to chemicals, fluids, ozone, electrical heat and the effects of aging. Many types of synthetic rubber are flame-resistant, so it can be used as insulation for electrical devices. It also remains flexible at low temperatures and is resistant to grease and oil. Because of this synthetics offer excellent results for applications in extreme temperatures and corrosive environments.

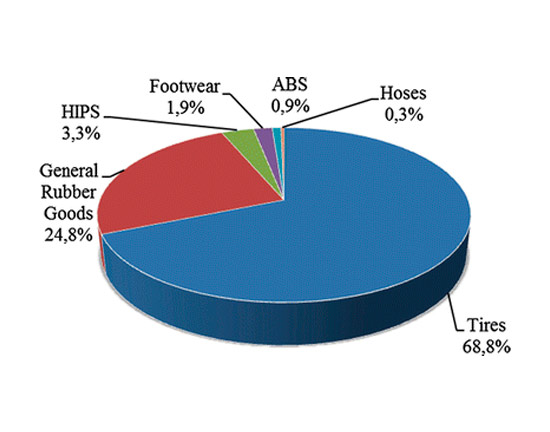

The applications for synthetic rubber are nearly limitless. Perhaps the largest consumer of these rubber raw materials is the automotive industry and rubber industry. Tires, seals, o-rings, gaskets, rubber hoses, belts, and other components throughout the vehicle are often made with synthetic rubber. The aerospace industry uses synthetic rubbers for many of these same components. The construction industry also relies heavily on synthetic rubber for seals, flooring, roofing, and other applications.

Another major consumer of synthetic rubbers is the medical industry. Synthetic rubbers are safe for patients who are sensitive or allergic to latex and thus are often used for tubing and other products that come into direct contact with the skin. Healthcare professionals also rely on synthetic rubber for protective equipment, medical components, and much more.

Everyday consumers will find synthetic rubber all throughout their daily lives. Synthetic rubber tyres, shoes, sporting goods, kitchen tools, and even chewing gum contain synthetic rubber(Butyl rubber).

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.