Preform-to-Fiber drawing uses the same basic technique that is used to produce the glass telecommunication fibers that span the globe and enable world-wide communications. Adobe Stock

Fibers and textiles date back to the beginning of civilization itself, yet remarkably, the fundamental properties of these materials have remained largely unchanged for millennia. By and large, natural fibers such as cotton and wool, and synthetic fibers such as nylon and polyester form the foundation for the vast majority of textile products, yet functionally, these materials are relatively simple.

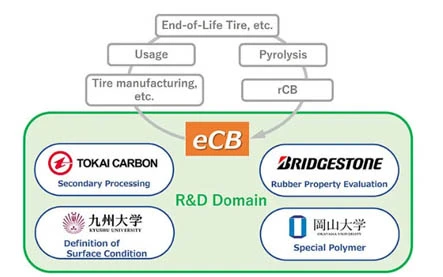

As such, humans continue to expect traditional features from their textile-based products, primarily used for protection, aesthetic, and cultural purposes. In the early 2000s, a fundamental shift in fiber technology occurred – a new class of fibers were invented, dubbed multi-material fibers[1]. Invented by MIT scientists in 2000, and subsequently spread throughout laboratories across the world over the past couple of decades, this new class of fibers enables the integration of disparate materials, including semiconductors, metals and insulators within a fiber form factor.

The ability to broaden the scope of materials processable into fibers has given rise to drastically new fiber functionalities, including fibers that can sense and actuate, store energy, change color, emit and detect light, store data, communicate, and more[1-6]. As a result, new textile-based applications emerged with increasingly sophisticated functions, such as fabrics with embedded sensors for healthcare, climate-adaptive textiles for self-regulated cooling, soft fabric light emitting displays and more.

Advanced fibers with microelectronics are enabling radically new applications owing to the unique nature of this technology. For example, jointly with our partners at MIT Lincoln Laboratory, AFFOA is advancing fiber and fabric systems motivated by national security needs. Three classes of applications are discussed below, as depicted in Figure 4, which demonstrate just a few examples of the broad range of capabilities enabled by multi-material fibers.

Large Area Undersea Sensing: Given the length of these fibers and the ability to introduce semiconductor chips along their axis, the opportunity for large area distributed sensing becomes possible. One example where this technology is paving the way towards a revolutionary capability for the Department of Defense is in the area of undersea sensing. Large area oceanographic data is critical for planning and executing undersea missions from the tactical to strategic levels in the maritime domain.

An alternative communication scheme uses light to transmit data. Unlike radio frequency waves, light can be directional (e.g., sent over a laser), thereby greatly reducing the probability of intercept or detection. By embedding light detecting and light emitting fibers into the fabric of a soldier’s uniform, the fabric itself becomes a communication system – it can receive and transmit optical data. AFFOA in collaboration with MIT Lincoln Laboratory has demonstrated several fabric-based light communications systems using this approach. Specific use-cases range from improved identification of friend versus foe schemes (Figure 4, Center) to soldier-to-soldier communications.

Physiological Status Monitoring: Continuous, real-time physiological status monitoring (PSM) for early detection of acute hypoxia, enabling action prior to impairment or injury, is a mission-critical system need for High Altitude Low Opening (HALO) jumpers (Figure 4, Right).

Existing technologies to address this need are insufficient due to inaccuracies and user-friction associated with conventional wrist-worn PSM wearables. Sponsored by the U.S. Army Research Institute of Environmental Medicine (USARIEM) and in partnership with end-users from the US Air Force Special Operations Command, AFFOA in collaboration with MIT Lincoln Laboratory has developed a fabric headband sensor system, enabling increased measurement accuracy.

The fabric contains embedded microelectronic components that measure key physiological status markers including temperature, heart rate, and blood-oxygen levels. Data is transmitted wirelessly from the fabric to a smartphone, with an edge-computing architecture supporting over 40 hours of continuous battery life. Many headbands can communicate to a single smartphone, enabling the mission commander or medic rapid access to the readiness status of multiple jumpers in real-time. This system has undergone initial end-user testing in a simulated high-altitude environment and has successfully demonstrated the ability to identify moments of induced hypoxia. Feedback from these tests is informing improvements to fit that will be included in future development efforts.

Multi-material fibers drawn from a preform are enabling a new class of functional fiber and fabric systems. AFFOA and its Fabric Innovation Network are working to bring these new technologies to market with pull from both the Department of Defense and commercial industry. AFFOA has the internal subject matter expertise and equipment to prototype new multi-material fiber architectures as well as scale-up existing fiber technologies and is always looking for new applications and opportunities to collaborate with domestic partners to bring them to market.

AFFOA is a non-profit, public-private partnership founded in 2016 as one of the nine DoD Manufacturing USA Innovation Institutes. Headquartered in Cambridge, MA, AFFOA’s mission is to rekindle the domestic textiles industry by leading a nationwide enterprise for advanced fiber & fabric technology and manufacturing innovation, enabling revolutionary new system capabilities for commercial and defense applications.

To catalyze the development of advanced functional fibers and strengthen the domestic textile industrial base, AFFOA has assembled a Fabric Innovation Network (FIN) made up of 150+ member organizations including startups, universities, manufacturers, commercial industry and defense partners to bring advanced fiber technologies to market.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt