Introduced as a lightweight alternative to traditional EPDM rubber (Ethylene Propylene Diene Terpolymer), Cooper Standard TPV hoses perform like cross-linked rubber but are processed like a thermoplastic tube without the need for material compounding or curing. Hoses made with TPV offer considerable material weight savings, as much as 40% compared to EPDM hoses, and provide increased flexibility compared to thermoplastic tubes of similar size. Our TPV hoses also meet the needs of lower temperatures and system pressures that electric vehicles require.

Cooper Standard is a global leader in fluid handling solutions. The Company's TPV hose solutions further complement its complete portfolio of thermal management solutions, independent of a vehicle's architecture, that also include EPDM hose, mono-wall and multi-layer thermoplastic tubing and quick connectors for both SAE and VDA type connections.

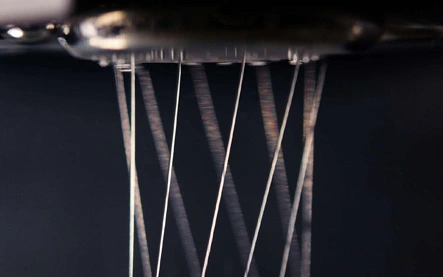

TPV hoses from Cooper Standard provide a smooth internal surface, resulting in a solution that minimizes the impact of pressure losses in a coolant system. Hoses are flexible, but strong using a layer of reinforcing yarn for flexibility during installation and to allow dynamic movement of mating components. TPV hoses connect to the vehicle through traditional EPDM hose connections, such as clamps, or to one of Cooper Standard's industry-leading quick connector solutions.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt