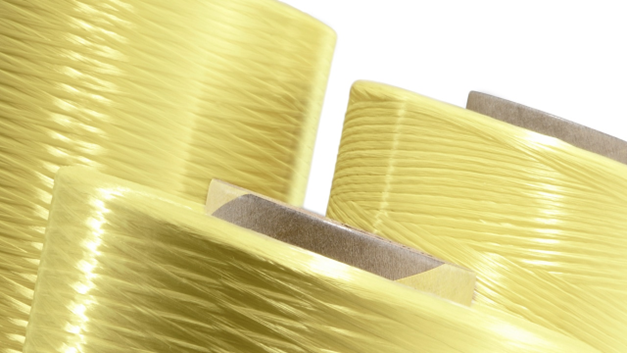

Aramid is a high-performance chemical synthetic fiber. Aramid, carbon fiber, and ultra-high molecular weight polyethylene (UHMWPE) are known as the world's three major high-performance fiber materials. The full name of aramid is "aromatic polyamide fiber", and its English name is "Aramid Fiber", which refers to long-chain synthetic polyamide fibers with at least 85% of amide bonds directly connected to aromatic rings. Aramid fiber has excellent properties such as low density, high modulus, high strength, cut resistance, corrosion resistance, high temperature resistance, insulation and flame retardancy. Its strength is 5 to 6 times that of steel wire, its modulus is 2 to 3 times that of steel wire or glass fiber, its toughness is 2 times that of steel wire, and its weight is only about 1/5 of that of steel wire. At a temperature of 560 degrees, it does not decompose or melt, and its comprehensive performance is outstanding. Commercial aramid products are mainly meta and para.

According to the type of aromatic ring, aramid can be divided into two categories: fully aromatic polyamide fiber and heterocyclic aromatic polyamide fiber; according to the position where the amide bond is connected to the benzene ring, it can be divided into meta, para and ortho positions. There are two main types of aramid that have been commercially produced and applied: meta-aramid (PMIA, 1313) and para-aramid (PPTA, 1414). The production technology of para-aramid is more difficult, and the product performance is better. Meta-aramid and para-aramid products are diversified and can meet the needs of many fields. Aramid products are formed by spinning the polymer after the polymerization of amide and acyl chloride. According to whether it is dyed, aramid is divided into colored silk and white silk; according to the spinning form, it is divided into filament and staple fiber. Meta-aramid also has conductive fiber, yarn and other product forms, and para-aramid twisted yarn, woven fabric, pulp and other differentiated products can meet the use needs of different fields.

Aramid has excellent ductility, high temperature resistance and flame retardancy. Among the three materials, aramid has the best ductility, and the elongation at break of meta-aramid can reach 25~40%, which is more than ten times that of carbon fiber and UHMWPE. The elastic modulus of para-aramid is relatively high, up to 120GPa, indicating that its material has high stiffness and small elastic deformation; carbon fiber is the most resistant to high temperatures among the three materials, with an operating temperature of up to 2000℃ and a decomposition temperature of up to 3700℃. The operating temperature of aramid is -196~250℃, which can meet daily use. The oxygen index of aramid and carbon fiber is as high as 28% or more, and the flame retardancy is good.

UHMWPE has the lowest density, but its oxygen index is as low as 17.3%, which cannot achieve high temperature resistance and flame retardancy. Meta-aramid has excellent flame retardancy, high temperature resistance, insulation, chemical stability and radiation resistance. The amide group in the meta-aramid molecular chain is connected to the meta-phenyl group, which has no conjugation effect, low internal rotation potential energy, relatively good chain segment flexibility, and low crystallinity, so its modulus is low and its elongation is high, making it feel and comfortable as a fabric. Meta-aramid has excellent flame retardancy, high temperature resistance, insulation and chemical stability, and is widely used in fireproof materials, high-temperature conveyor belts, high-temperature filter materials, high-temperature protective fabrics, electrical insulation and heat insulation, etc.

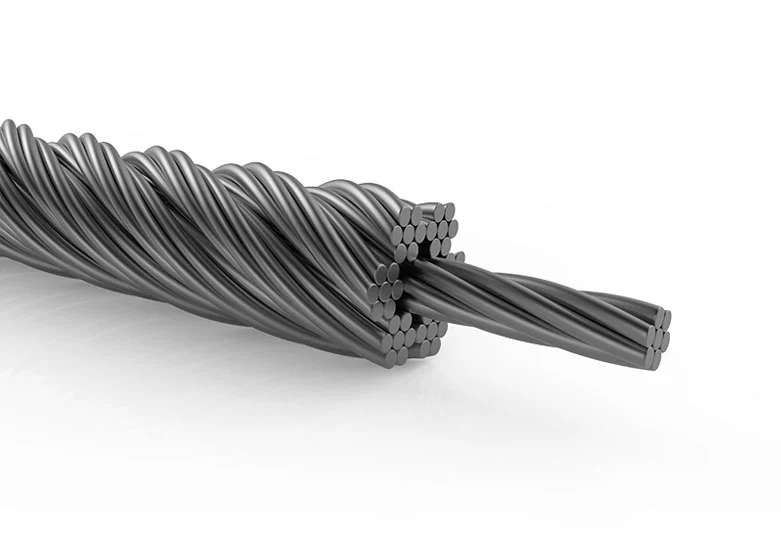

Para-aramid has high strength, high modulus, high temperature resistance, strong toughness, flame retardancy, chemical resistance, corrosion resistance and dimensional stability. Para-aramid has high strength, with a specific tensile strength of 5 to 6 times that of steel fiber and a specific modulus of 2 times that of steel fiber; the thermal decomposition temperature reaches 570°C, and it can be used for a long time at ±200°C; compared with carbon fiber, aramid is soft and non-brittle, and can resist strong impact; it has good dimensional stability, does not shrink in hot air, and has small deformation; it has good chemical corrosion resistance. The high crystallinity and strong intermolecular interaction of para-aramid can prevent chemicals from invading the polymer structure, and its performance is stable in the pH range of 2 to 12. Aramid is widely used as a reinforcing material. With the rapid development of industrial production and high-tech industries today, the demand for high-performance materials in industries such as automobiles, engineering machinery, microelectronics, communications, and ships is getting stronger and stronger, and the requirements are getting higher and higher. It is difficult for general materials to meet the needs.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt