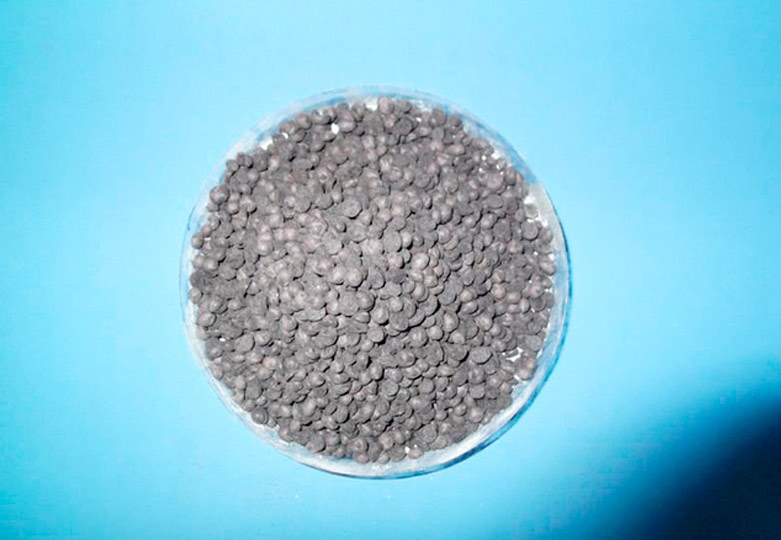

Depending on the different performance of different Rubber additives including rubber accelerator, rubber antioxidant, and PVI rubber chemical. The rubber auxiliary is mainly used in area of Rubber compoundings, Tyres, rubber conveyor belts, rubber hose, Airsprings and other rubber products.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.