Multifilament Yarns: Superior Strength, Endless Possibilities

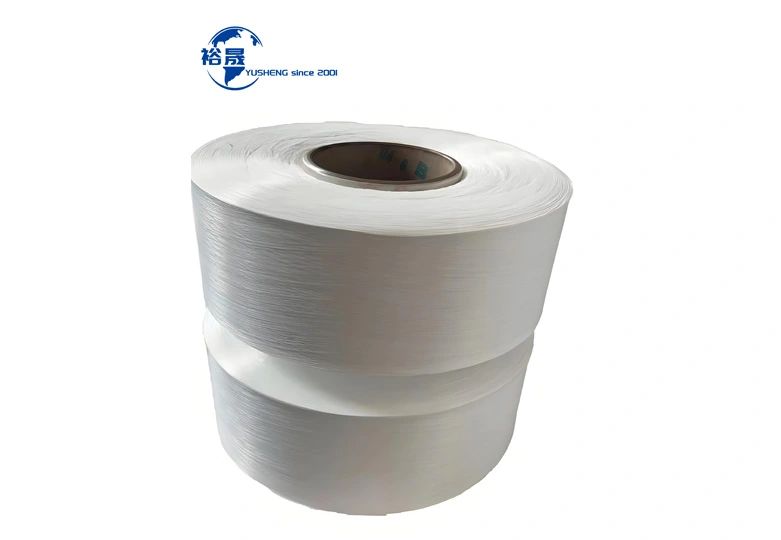

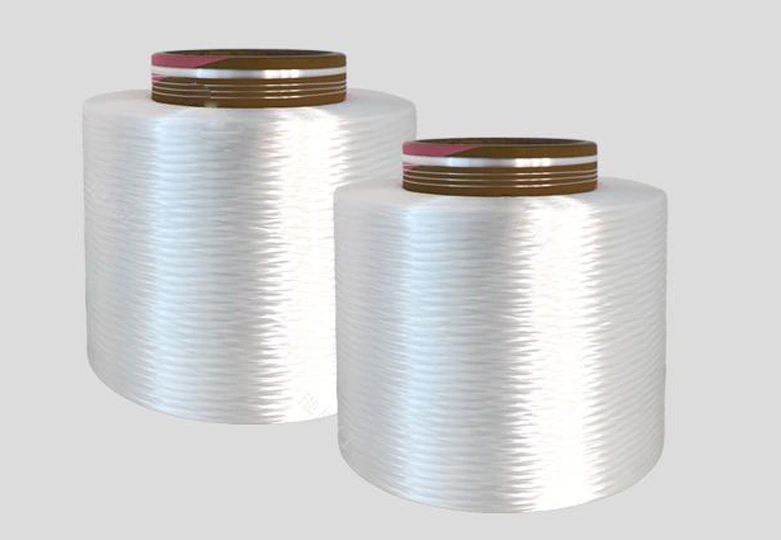

Multifilament yarns are composed of multiple filament fibers that are twisted or bundled together. Unlike monofilament yarns, which are made using a single-holed spinneret, multifilament yarns are produced using a spinneret with many small holes. This process ensures that all the extruded filaments are evenly drawn out. YUSHENG offers a wide range of multifilament yarns, including nylon multifilament yarn, polyester multifilament yarn, and polypropylene (PP) multifilament yarn, all designed to meet the diverse needs of the textile industry.

Multifilament yarns have an incredibly wide range of applications across various industries. These multifilament yarns are used extensively in the production of specialized products such as Geo Textile Fabrics and Filter Fabrics, as well as everyday items like sewing threads. In addition, multifilament yarns play a critical role in manufacturing Woven Sacks, Webbings, Tapes, Sofa Sets, Safety Belts, Braids, Ropes, Tennis Rackets, and much more. Among the most popular types, nylon multifilament yarn, polyester multifilament yarn, and polypropylene (PP) multifilament yarn are widely utilized to meet diverse industrial and consumer needs.

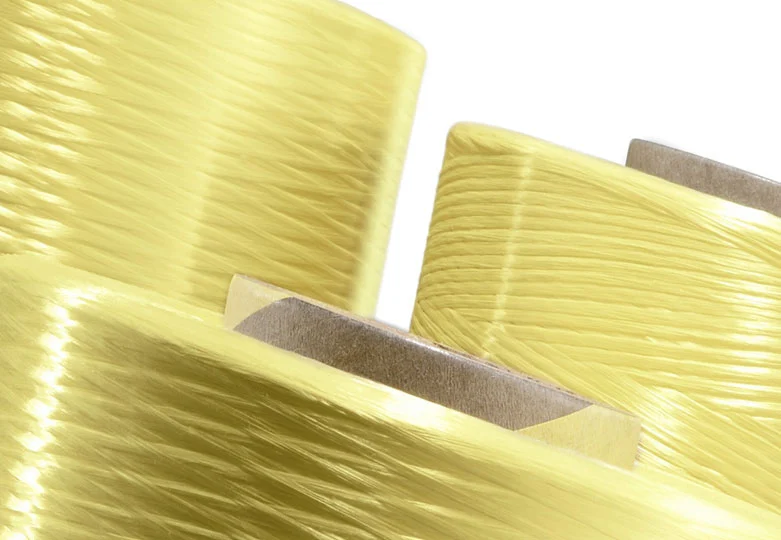

The nylon multifilament yarn is particularly valued for its strength and elasticity, making it ideal for producing braids, ropes, and safety belts. The high abrasion resistance of nylon multifilament yarns ensures durability in demanding applications, such as tennis rackets and webbings.

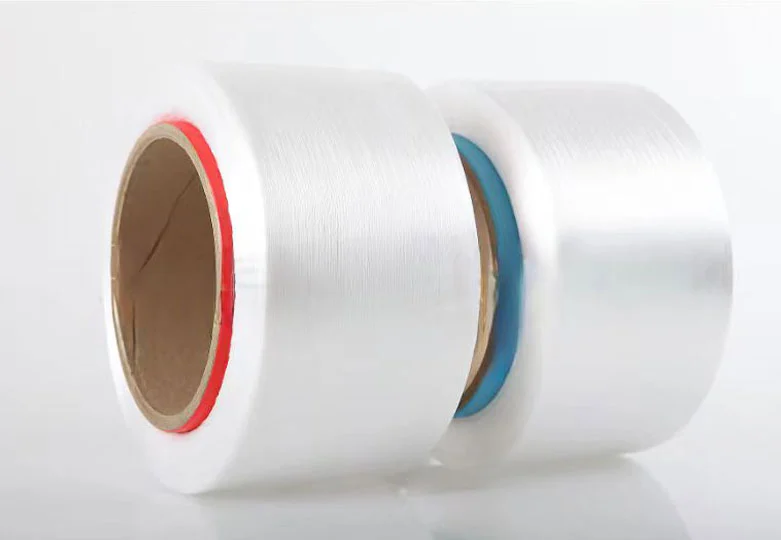

Polyester multifilament yarns are extensively used in the textile industry for their excellent dimensional stability and resistance to UV exposure. Polyester multifilament yarns are commonly employed in sewing threads, sofa sets, and webbings, as they provide a smooth texture along with long-lasting performance. The strength and resilience of multifilament polyester yarn also make it a preferred choice for safety belts and industrial tapes.

For applications requiring superior chemical resistance, polypropylene (PP) multifilament yarn is the material of choice. With its outstanding resistance to alkalis, acids, and moisture at normal temperature, polypropylene (PP) multifilament yarn is widely used in Geo Textile Fabrics and Filter Fabrics. The polypropylene (PP) multifilament yarn is also an excellent option for woven sacks, ropes, and other products exposed to harsh environmental conditions.

Fiber Structure & Production Process: Multifilament yarn consists of multiple continuous filaments (kilometer-long strands) twisted or grouped together, offering superior strength and uniformity. Spun yarn, in contrast, is made from short staple fibers (measured in centimeters) that are spun into yarn, creating a softer but less durable structure.

Surface Texture & Appearance: Multifilament yarn boasts a smooth, lustrous finish, ideal for applications requiring sleekness and durability. Spun yarn has a "hairy" surface due to loose fiber ends, providing a softer feel but lower tensile strength compared to multifilament yarn.

Strength & Durability: Multifilament yarn outperforms spun yarn in tensile strength, making it a top choice for high-performance textiles, industrial ropes, and medical sutures. Spun yarn, while softer and more flexible, lacks the structural integrity of multifilament yarn, limiting its use in heavy-duty applications.

Versatility in Applications: Multifilament yarn is widely used in technical textiles, sportswear, and high-strength fabrics due to its resilience. Spun yarn is common in everyday apparel and comfort fabrics where softness takes priority over durability.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.