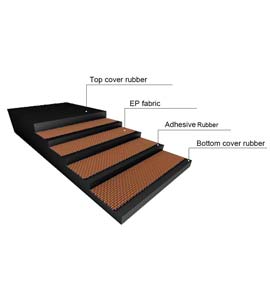

EP Belting Fabric are woven by Polyester yarns in warp direction and Nylon yarns in Weft direction. It has the advantages of high strength, lower elongation, high crimps in warp side, low heat shrinkage and heat-resisting.

EP fabric is especially suitable and widely used in traditional rubber industry for the production of long distance, high load and high speed conveyor belts.

Yusheng can provide all kinds of EP fabric according to customers' requirements.

NO. | ITEM | Unit | EP-80 | EP-100 | EP -125 | EP -150 | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | |||

1 | Material | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | |

2 | Ave breaking strength (min) | N\cm | 1050 | 450 | 1400 | 500 | 1600 | 650 | 1950 | 700 |

3 | Elongation at 10% load (max) | % | 2.0 | / | 2.0 | / | 2.0 | / | 2.0 | / |

4 | Breaking Elongation | % | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 |

5 | Hot air shrinkage 150C×30min (max) | % | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 |

6 | Adhesion (min) | N\2.54cm | 196 | 196 | 196 | 196 | ||||

7 | Weight per square metre | g\m2 | 320±20 | 350±20 | 435±20 | 520±20 | ||||

8 | Thickness | mm | 0.50±0.05 | 0.52±0.05 | 0.65±0.05 | 0.70±0.05 | ||||

9 | Warp Crimps | % | 4.0±1.0 | 4.5±1.0 | 5.0±1.0 | 5.5±1.0 | ||||

Note: Special spec. can be customized by the requirement/sample from customers.

NO. | ITEM | Unit | EP -160 | EP-200 | EP -250 | EP -300 | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | |||

1 | Material | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | |

2 | Ave breaking strength (min) | N\cm | 1950 | 700 | 2400 | 800 | 3100 | 900 | 3400 | 900 |

3 | Elongation at 10% load (max) | % | 2.0 | / | 2.0 | / | 2.0 | / | 2.0 | / |

4 | Breaking Elongation | % | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 |

5 | Hot air shrinkage 150C×30min (max) | % | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 |

6 | Adhesion (min) | N\2.54cm | 196 | 196 | 196 | 196 | ||||

7 | Weight per square meter | g\m2 | 520±20 | 620±20 | 780±30 | 860±30 | ||||

8 | Thickness | mm | 0.70±0.05 | 0.85±0.05 | 1.00±0.10 | 1.2±0.10 | ||||

9 | Warp Crimps | % | 5.5±1.0 | 6.0±1.0 | 6.5±1.0 | 6.5±1.0 | ||||

Note: Special spec. can be customized by the requirement/sample from customers.

NO. | ITEM | Unit | EP -315 | EP-350 | EP -400 | EP -500 | ||||

Warp | Weft | Warp | Weft | Warp | Weft | Warp | Weft | |||

1 | Material | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | Polyester | Nylon66 | |

2 | Ave breaking strength (min) | N\cm | 3600 | 900 | 3900 | 900 | 4500 | 950 | 5600 | 1000 |

3 | Elongation at 10% load (max) | % | 2.0 | / | 2.0 | / | 2.0 | / | 2.5 | / |

4 | Breaking Elongation | % | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 | ≥14 | ≤45 |

5 | Hot air shrinkage 150C×30min (max) | % | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 | 3.0 | 1.0 |

6 | Adhesion (min) | N\2.54cm | 196 | 196 | 196 | 196 | ||||

7 | Weight per square meter | g\m2 | 930±40 | 1050±30 | 1200±40 | 1510±50 | ||||

8 | Thickness | mm | 1.25±0.10 | 1.3±0.1 | 1.4±0.1 | 1.8±0.2 | ||||

9 | Warp Crimps | % | ≥5.0 | ≥5.0 | ≥5.0 | ≥6.0 | ||||

Note: Special spec. can be customized by the requirement/sample from customers.

Packing In rolls

Standard packing materials and methods.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt