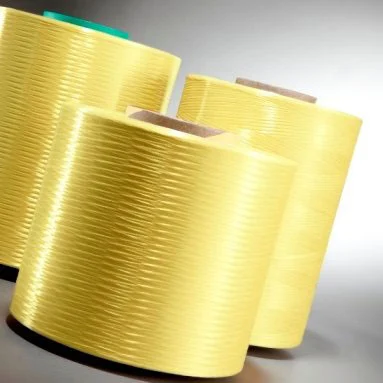

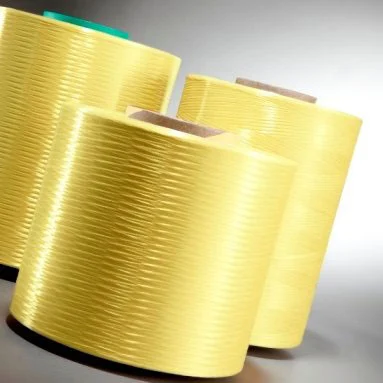

Premium Aramid Yarn Solutions: Flame-Resistant & High-Tenacity

Aramid, short for "aromatic amide", represents the gold standard in high-performance synthetic fibers. Aramid yarn delivers unparalleled reinforcement, boasting five times the tensile strength of iron at the same weight while maintaining exceptional heat resistance and low cutability. At Yusheng, we specialize in manufacturing premium aramid yarn tailored for industries demanding high strength, flame resistance, and lightweight properties.

Yusheng has the perfect aramid yarn solution to meet your specific technical requirements and performance expectations. Our state-of-the-art production capabilities allow us to offer three specialized grades of performance aramid yarn: standard tenacity aramid yarn, high tenacity aramid yarn and high modulus aramid yarn.

Standard Tenacity

Linear Density | Filament Count | Tenacity | Breaking Force | Elongation at Break | Y Modulus | Fresh | |||

denier | dtex | ea | g/d | cN/dtex | N | % | g/d | Gpa | % |

100 | 110 | 66 | ≥23 | ≥21 | 23 | 3.2-3.6 | 760 | 97 | 0.8-1.2 |

200 | 220 | 133 | ≥23 | ≥21 | 46 | 3.2-3.6 | 760 | 97 | 0.8-1.2 |

400 | 440 | 266 | ≥23 | ≥21 | 92 | 3.2-3.6 | 750 | 95 | 0.8-1.2 |

600 | 660 | 400 | ≥23 | ≥21 | 138 | 3.2-3.6 | 750 | 95 | 0.8-1.2 |

840 | 930 | 560 | ≥23 | ≥21 | 193 | 3.2-3.6 | 720 | 92 | 0.8-1.2 |

1000 | 1100 | 666/444 | ≥23 | ≥21 | 230 | 3.2-3.6 | 710 | 90 | 0.8-1.2 |

1500 | 1670 | 1000/666 | ≥23 | ≥21 | 345 | 3.2-3.6 | 680 | 86 | 0.8-1.2 |

2000 | 2200 | 1332 | ≥22 | ≥21 | 450 | 3.2-3.6 | 670 | 85 | 0.8-1.2 |

3000 | 3300 | 2000 | ≥22 | ≥20 | 690 | 3.2-3.6 | 660 | 84 | 0.8-1.2 |

High Tenacity

Linear Density | Filament Count | Tenacity | Breaking Force | Elongation at Break | Y Modulus | Fresh | |||

denier | dtex | ea | g/d | cN/dtex | N | % | g/d | Gpa | % |

200 | 220 | 133 | ≥26 | ≥24 | 52 | 3.2-3.7 | 760 | 97 | 0.8-1.2 |

400 | 440 | 266 | ≥26 | ≥24 | 104 | 3.2-3.7 | 760 | 97 | 0.8-1.2 |

600 | 660 | 400 | ≥26 | ≥24 | 156 | 3.2-3.7 | 760 | 97 | 0.8-1.2 |

840 | 930 | 560 | ≥26 | ≥24 | 218 | 3.2-3.7 | 740 | 94 | 0.8-1.2 |

1000 | 1100 | 666 | ≥26 | ≥24 | 260 | 3.2-3.7 | 740 | 94 | 0.8-1.2 |

1500 | 1670 | 1000 | ≥26 | ≥24 | 380 | 3.2-3.7 | 710 | 92 | 0.8-1.2 |

3000 | 3300 | 2000 | ≥25 | ≥23 | 750 | 3.2-3.7 | 690 | 88 | 0.8-1.2 |

High Modulus

Linear Density | Filament Count | Tenacity | Breaking Force | LASE 0.5% 1.0% | Elongation at Break | Y Modulus | Fresh | ||||

denier | dtex | ea | g/d | cN/dtex | N | N | N | % | g/d | Gpa | % |

1140 | 1270 | 1000 | ≥22 | ≥20 | 250 | 56 | 105 | 2.5-3.0 | 960 | 120 | 0.8-1.2 |

1420 | 1580 | 1000 | ≥22 | ≥20 | 312 | 72 | 130 | 2.5-3.0 | 960 | 120 | 0.8-1.2 |

2840 | 3160 | 2000 | ≥22 | ≥20 | 624 | 135 | 248 | 2.5-3.0 | 900 | 115 | 0.8-1.2 |

5680 | 6320 | 4000 | ≥21 | ≥19 | 1190 | 245 | 433 | 2.5-3.0 | 830 | 105 | 0.8-1.2 |

7100 | 7900 | 5000 | ≥21 | ≥19 | 1490 | 300 | 550 | 2.5-3.0 | 790 | 100 | 0.8-1.2 |

8520 | 9480 | 6000 | ≥21 | ≥19 | 1780 | 335 | 620 | 2.5-3.0 | 720 | 92 | 0.8-1.2 |

9940 | 11060 | 7000 | ≥21 | ≥19 | 2080 | 370 | 705 | 2.5-3.0 | 720 | 92 | 0.8-1.2 |

Aramid yarn stands out as a high-performance material, celebrated for its remarkable strength, durability, and resistance to extreme conditions. Aramid yarn offers a unique combination of properties that make it indispensable for applications requiring reliability and longevity.

Unmatched Tensile Strength: One of the most defining features of aramid yarn is its extraordinary tensile strength, often five times greater than steel on a weight-for-weight basis. This strength allows aramid yarn to withstand extreme mechanical stress without breaking, making it a cornerstone of industrial durability.

Superior Heat and Flame Resistance: Aramid yarn excels in environments where high temperatures are a concern. This thermal stability ensures that aramid yarn maintains its integrity in extreme heat, protecting both equipment and personnel. For example, aramid yarn in protective clothing can resist ignition and prevent burn injuries, a critical feature for safety-focused industries.

Outstanding Durability and Abrasion Resistance: Durability is a hallmark of aramid yarn, driven by its resistance to abrasion, wear, and mechanical damage. The tightly packed molecular structure of aramid yarn minimizes surface wear, making it suitable for high-friction environments. This durability reduces maintenance costs and extends the lifespan of products, offering significant value for industries relying on aramid yarn.

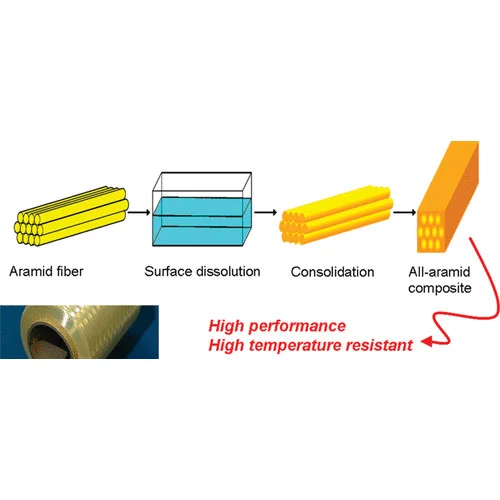

YUSHENG's aramid yarn is redefining strength and versatility in material science. Engineered for excellence, our aramid yarn is the go-to solution for ballistic-protection products, ensuring superior safety in high-risk environments. But its applications don’t stop there — our cutting-edge aramid yarn enhances performance in composites, cut-protection products, and elastomer reinforcements, delivering unmatched durability and reliability.

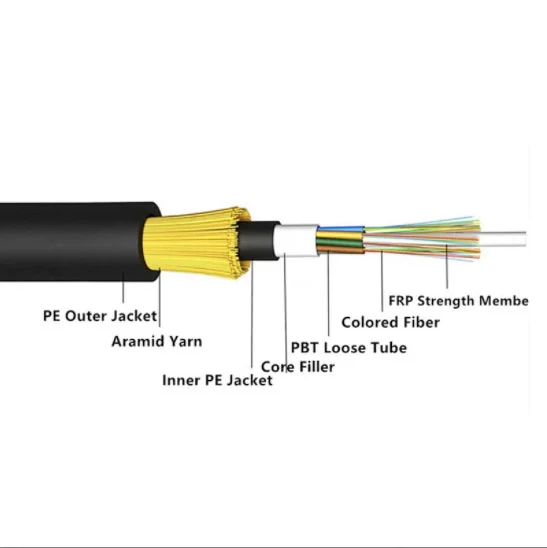

Need extreme heat resistance? YUSHENG's aramid yarn excels in heat-protection products, safeguarding against intense temperatures. Our aramid yarn is also the backbone of optical fiber cables and reinforced thermoplastic pipes, providing structural integrity where it matters most. For industries demanding robust solutions, our aramid yarn strengthens ropes and cables, ensuring longevity under stress.

And let’s not forget specialized applications — YUSHENG's aramid yarn is a game-changer for aramid cord fabrics used in special tires, offering enhanced traction and wear resistance. Whatever your challenge, our aramid yarn stands ready to deliver strength, safety, and innovation. Choose aramid yarn — choose excellence.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt