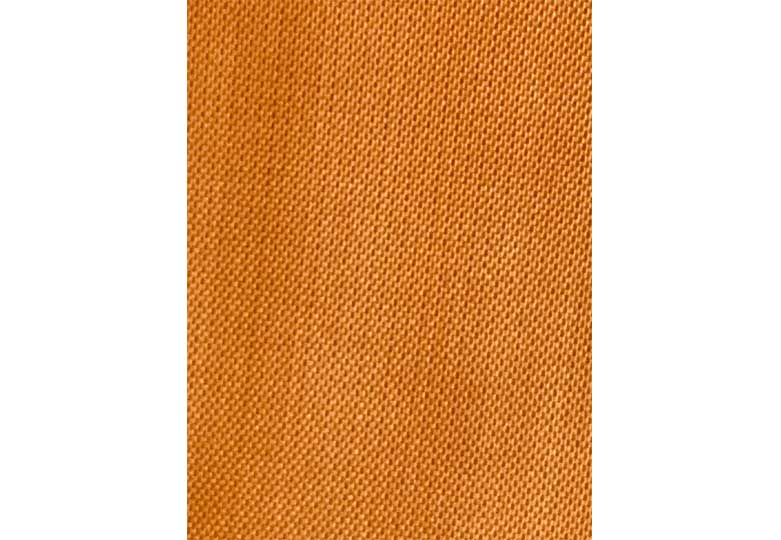

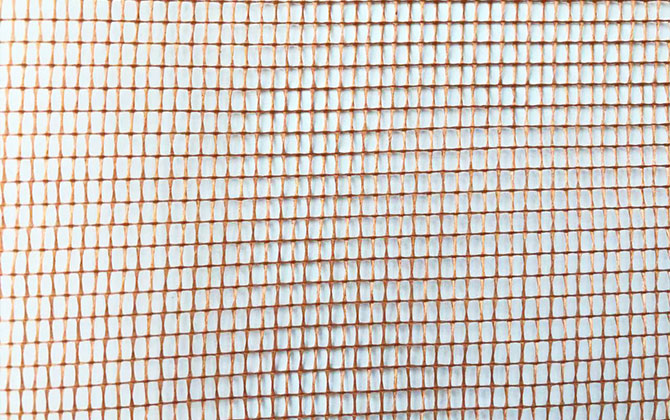

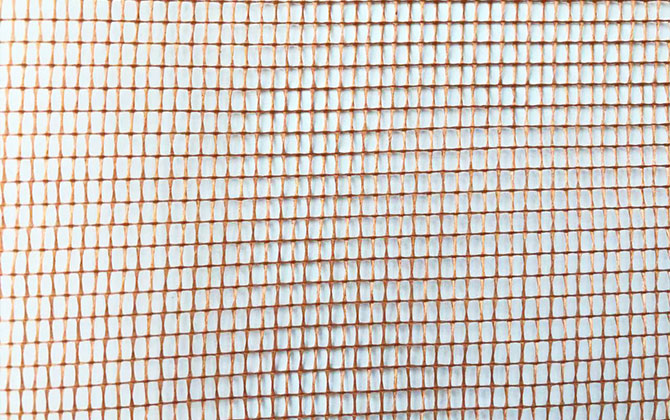

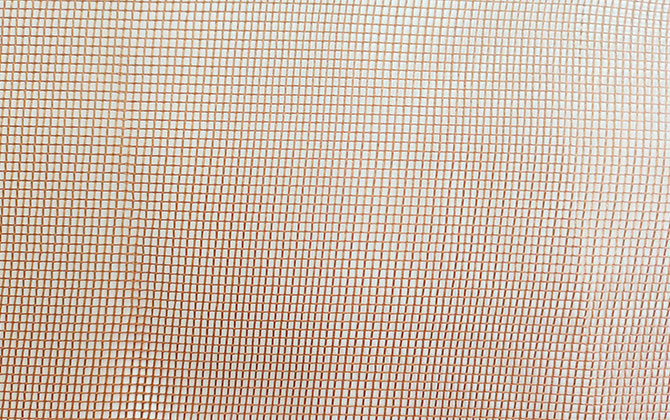

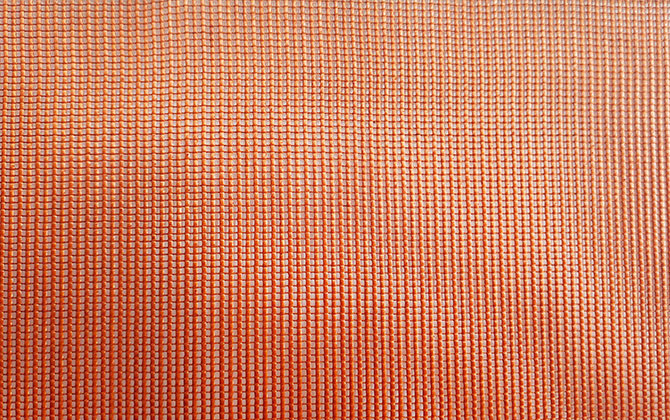

Leno fabric (also called Leno weave fabric or cross weave fabric) is a weave in which two warp yarns are woven around the weft yarns to provide a strong yet sheer fabric. The standard warp yarn is paired with a skeleton or "doup" yarn; these twisted warp yarns grip tightly to the weft which causes the durability of the leno mesh fabric. Leno weave produces an open leno mesh fabric with almost no yarn slippage or misplacement of threads. YUSHENG, a professional leno weave fabric manufacturer, provides a wide range of leno woven fabric. Our leno textile is manufactured using advanced techniques to provide exceptional durability, resistance to wear, and unparalleled consistency.

Leno weave fabric, also known as leno cloth, is a type of weave commonly used in textile production. This unique weaving technique creates a strong, durable fabric that is often referred to as leno mesh fabric due to its open, airy structure. Leno textiles are highly valued for their stability and resistance to distortion. Leno weave fabric has some advantages, including:

Open Structure: Leno weave creates an open, airy structure with a distinct pattern. The open structure of leno textile allows for better breathability and ventilation in the fabric, making it suitable for warm weather or applications where air circulation is important.

Strength and Durability: Leno weave fabrics tend to be strong and durable. The interlacing of warp and weft yarns in a leno weave pattern enhances the stability and resistance to tearing.

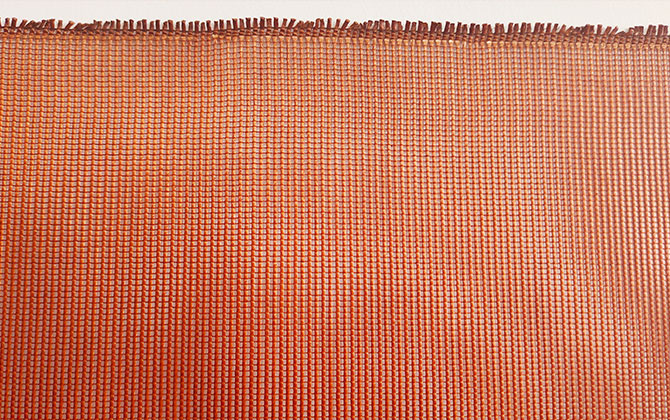

Prevention of Fraying: The leno weave helps prevent fraying at the edges of the fabric. This can be particularly beneficial in applications where the fabric edges are exposed to wear and tear.

Unique Aesthetic Appeal: The distinct appearance of leno weave, with its characteristic leno mesh-like pattern, gives the fabric a unique and interesting visual appeal. This can be advantageous for designers looking to create leno woven fabrics with a special texture or pattern.

Versatility: Leno weave fabrics can be used for a variety of purposes. Leno textiles are often employed in the production of mosquito nets, mesh bags, window curtains, and other applications where a combination of strength and ventilation is desirable.

Ease of Dyeing and Printing: Leno weave fabrics may offer ease of dyeing and printing due to their open structure, allowing dyes and prints to penetrate more easily.

Lightweight: Generally, leno weave fabrics are lightweight, making them suitable for applications where a lighter material is preferred.

ITEM /SPEC | UNIT | 210D/1 * 420D/1 | 210D/1 * 420D/1 | 840D/1 * 1260D/1 | 1680D/1 * 2520D/1 | 500D/1 * 500D/1 | 1000D/1 * 1000D/1 | 1000D/1 * 1500D/1 | Method |

FABRIC PROPERTIES | |||||||||

Content | Nylon 6/66 | Nylon 6/66 | Nylon 6/66 | Nylon 6/66 | Polyester | Polyester | Polyester | ||

Width | cm | TBD | TBD | TBD | TBD | TBD | TBD | TBD | - |

PHYSICAL AND MECHANICAL PROPERTIES | |||||||||

Warp Twist | T/m | TBD | TBD | TBD | TBD | TBD | TBD | TBD | GB/T 14345 |

Weft Twist | T/m | TBD | TBD | TBD | TBD | TBD | TBD | TBD | GB/T 14345 |

Warp Density | ends/10cm | (33±1)x2 | (54±1)x2 | (41±1)x2 | (32±1)x2 | (40±1)x2 | (40±1)x2 | (33±1)x2 | GB/T 4668 |

Weft Density | ends/10cm | 50±2 | 70±2 | 40±2 | 36±2 | 40±2 | 40±2 | 34±2 | GB/T 4668 |

Warp Breaking Load | N/5cm | ≥450 | ≥750 | ≥2500 | ≥3750 | ≥1000 | ≥2600 | ≥2000 | GB/T 32108 |

Weft Breaking Load | N/5cm | ≥750 | ≥950 | ≥1850 | ≥3050 | ≥500 | ≥1400 | ≥1500 | GB/T 32108 |

Warp Elongation at break | % | 20±5 | 20±5 | 25±5 | 25±5 | 25±5 | 25±5 | 25±5 | GB/T 32108 |

Weft Elongation at break | % | 30±5 | 30±5 | 30±5 | 30±5 | 30±5 | 30±5 | 30±5 | GB/T 32108 |

Dip for Tire Compound | - | RFL | RFL | RFL | RFL | RFL | RFL | RFL | - |

Adhesion | N/inch | ≥220 | ≥220 | ≥220 | ≥220 | ≥220 | ≥220 | ≥220 | GB/T 6759 |

Weight | g/m2 | 50±10 | 75±10 | 160±15 | 300±20 | 80±10 | 160±15 | 160±15 | GB/T 4669 |

Water Content | % | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | GB/T 6503 |

Thickness | mm | 0.35±0.05 | 0.35±0.05 | 0.57±0.05 | 0.9±0.05 | 0.5±0.05 | 0.7±0.05 | 0.7±0.05 | GB/T 36020 |

Shrinkage in hot air 30min@150°C | % | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | GB/T 36020 |

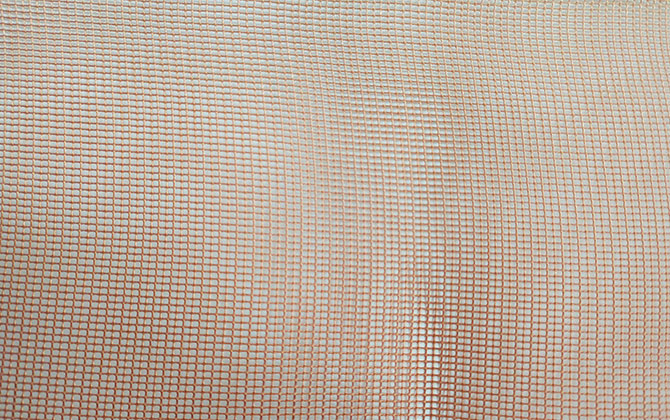

Leno weave fabric, also known as leno textile or leno cloth, is a type of woven fabric that is characterized by its unique leno weave structure. The weaving technique for leno woven fabric involves crossing warp yarns over each other in pairs to create a stable and open-weave structure. The leno weave fabric finds applications in various industries due to its specific properties. PP Leno fabric refers to a specific type of leno fabric that is made from polypropylene (PP) yarns. Polypropylene is a synthetic material known for its strength, durability, and resistance to moisture and chemicals. Leno fabric made from PP yarns inherits these properties, making it suitable for various applications.

PP leno fabric is commonly used in industries such as agriculture, construction, packaging, and geotextiles. Its sturdy mesh-like structure provides excellent breathability and allows for the passage of air and water, making this leno weave fabric ideal for applications like shade nets, agricultural nets, packaging sacks, and erosion control.

The use of polypropylene in leno fabric adds further advantages, such as resistance to UV rays, mildew, and rotting. This makes PP leno fabric a reliable choice for outdoor and demanding environments where durability and performance are crucial.

Leno mesh fabric, also known as leno woven fabric or leno fabric, which allows light and air to pass through freely, is used in any area where a sheer, open leno weave fabric that will not bruise (where the threads shift away from their original positions, disturbing the uniformity of the weave) is required. If a simple in-and-out flat weave were woven very loosely to achieve a sheer fabric, the threads would tend towards this bruising. Leno weaves are often used for window treatments and sheer layers for fine clothing. When made with glass fiber or other strong yarns or when permeated with a strengthening compound, the leno mesh can be used as an engineering material in construction. Due to the openness of the fabric, if a solid covering is required in a construction context, the leno woven fabric is often used in conjunction with other weave styles.

We Value Your Privacy.

Our website uses cookies to improve your experience. By clicking "Accept All Cookies", you agree to the storing of cookies on your device to enhance site navigation, analyze site usage, and assist in our marketing efforts.

English

English 日本語

日本語 한국어

한국어 français

français Deutsch

Deutsch Español

Español italiano

italiano русский

русский português

português العربية

العربية tiếng việt

tiếng việt